Adhesives & Sealants

Industry Overview

Key Features

The effectiveness of an adhesive or sealant depends on its ability to wet and adhere to the substrate. This is influenced by the surface energy of the substrate, the surface tension of the adhesive, and the cleanliness or treatment of the surface. Poor wetting leads to weak bonds, delamination, or failure under stress.

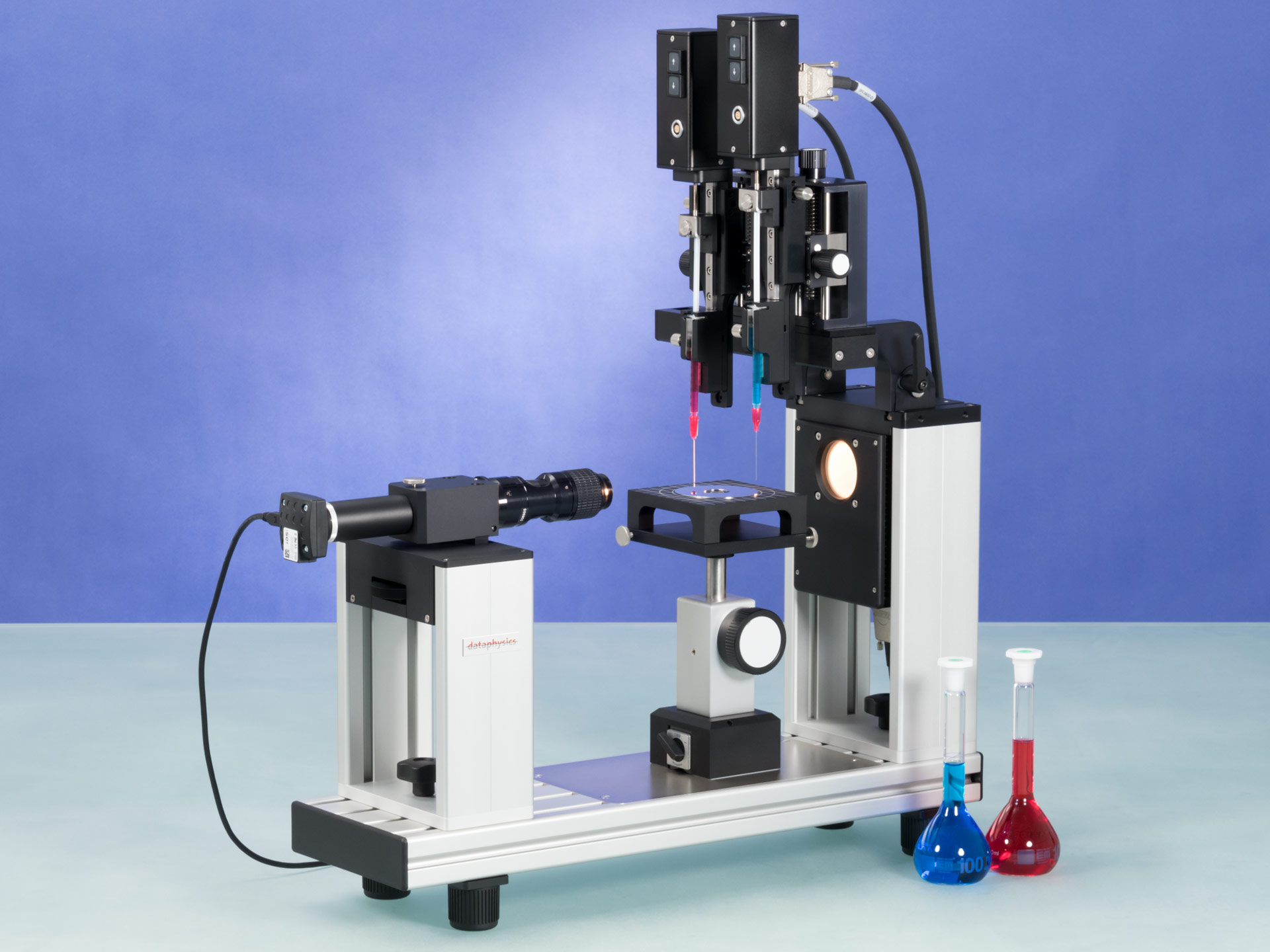

DataPhysics Instruments addresses these challenges with a suite of tools designed to characterize surface and interfacial properties. The OCA series measures contact angles and surface energy, providing insights into how well an adhesive will spread on a given surface. The DCAT tensiometer evaluates surface and interfacial tension, crucial for understanding the interaction between adhesives and substrates. The PCA 200 offers portable contact angle measurement for in-field quality control.

Surface preparation is a critical step in adhesive bonding. Techniques such as plasma treatment, chemical etching, or mechanical abrasion are used to increase surface energy and remove contaminants. DataPhysics devices allow users to quantify the effectiveness of these treatments by comparing contact angle and surface energy values before and after processing.

In formulation development, understanding the rheological and interfacial behavior of adhesives helps optimize viscosity, flow, and curing characteristics. This ensures that adhesives not only bond effectively but also perform reliably over time and under varying conditions.

Furthermore, DataPhysics tools support quality assurance by enabling consistent, repeatable measurements that can be integrated into production workflows. This reduces variability, enhances product reliability, and supports compliance with industry standards.

Typical Tests & Applications

1. Contact Angle Measurement (OCA, PCA 200)

Purpose: Assess how well an adhesive wets a substrate.

Application: Predict bond strength and identify surface contamination.

Benefit: Improve surface preparation and ensure consistent adhesion.

2. Surface Free Energy (SFE) Analysis (OCA)

Purpose: Determine the surface energy components of substrates.

Application: Match adhesives to substrates for optimal bonding.

Benefit: Reduce trial-and-error in formulation and application.

3. Surface Tension & Interfacial Tension (DCAT)

Purpose: Measure the tension between adhesive and substrate.

Application: Evaluate compatibility and spreading behavior.

Benefit: Enhance wetting and minimize defects like bubbles or voids.

4. Dynamic Contact Angle & Hysteresis (OCA, DCAT)

Purpose: Analyze advancing/receding angles and adhesion hysteresis.

Application: Understand how adhesives behave under dynamic conditions.

Benefit: Predict long-term performance and failure modes.

5. Wetting Envelope & Spreading Coefficient (OCA Software)

Purpose: Visualize wetting behavior across different adhesives.

Application: Select the most suitable adhesive for a given surface.

Benefit: Optimize product design and reduce material waste.

These analytical capabilities empower R&D teams and quality engineers to fine-tune adhesive systems, validate surface treatments, and ensure robust, durable bonds across a wide range of applications. With DataPhysics Instruments, the adhesives and sealants industry gains the precision and insight needed to meet modern performance demands.

Industry Resources

No Resources Available

We're currently updating our resource library for this industry. Check back soon or contact us to request specific documentation.

Request DocumentationSupporting Products

Contact Angle & Surface Tension

Contact Angle & Surface Tension

DCAT – Dynamic Contact Angle measuring devices and Tensiometer

The versatile DCAT Series combines dynamic contact angle measuring devices and force tensiometers to...

Contact Angle & Surface Tension

Contact Angle & Surface Tension

OCA – Optical contact angle measuring and contour analysis systems

The OCA Series by DataPhysics comprises high-precision optical contact angle goniometers and drop-sh...

Contact Angle & Surface Tension

Contact Angle & Surface Tension

PCA – Portable Contact Angle Goniometer

The PCA 200 is a compact, handheld contact angle goniometer engineered for on-site, autonomous mea...

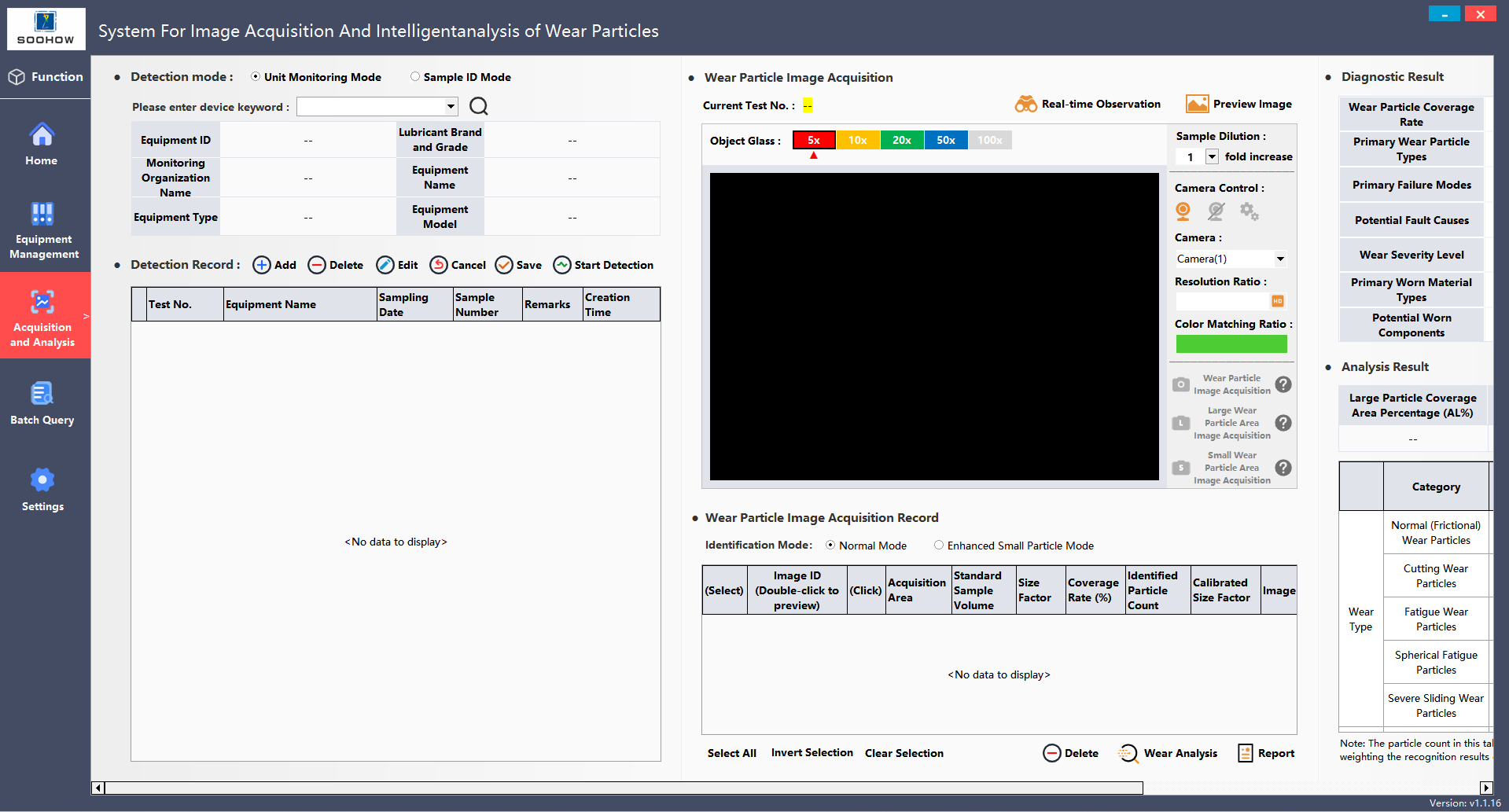

Oil Analysis

Oil Analysis

Wear Particle Image Acquisition & Intelligent Analysis System

This advanced system is a cutting-edge solution for modern Ferrography and oil condition monitoring....

Ready to Find the Right Solution?

Our team can help you select the perfect products for your Adhesives & Sealants applications