Main

تحليل الزيت

تحليل جسيمات التآكل

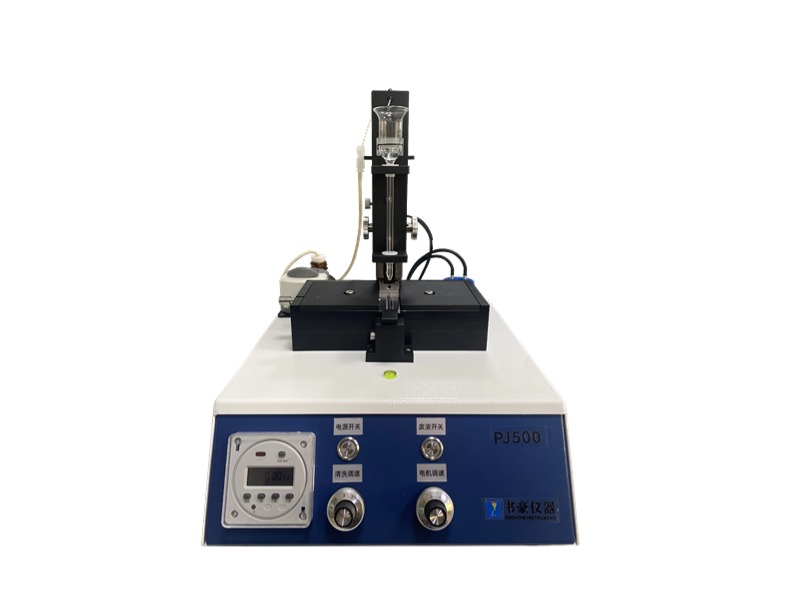

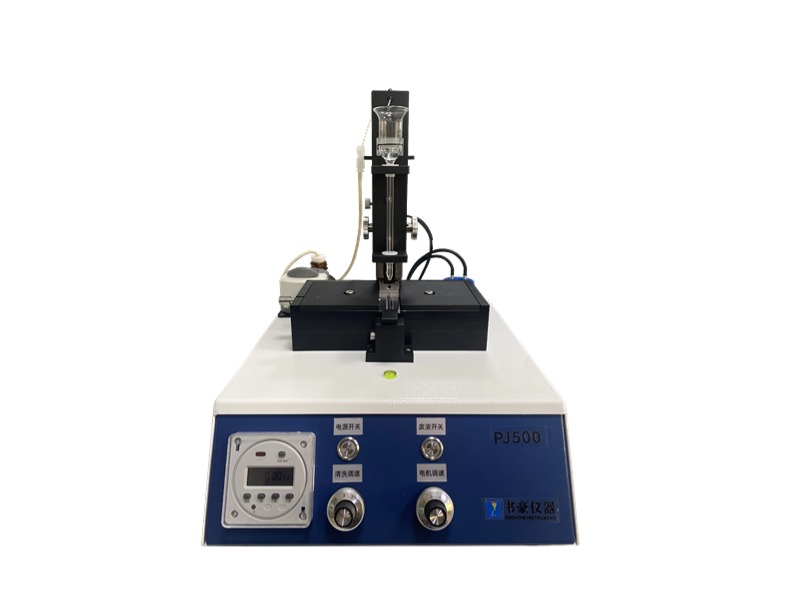

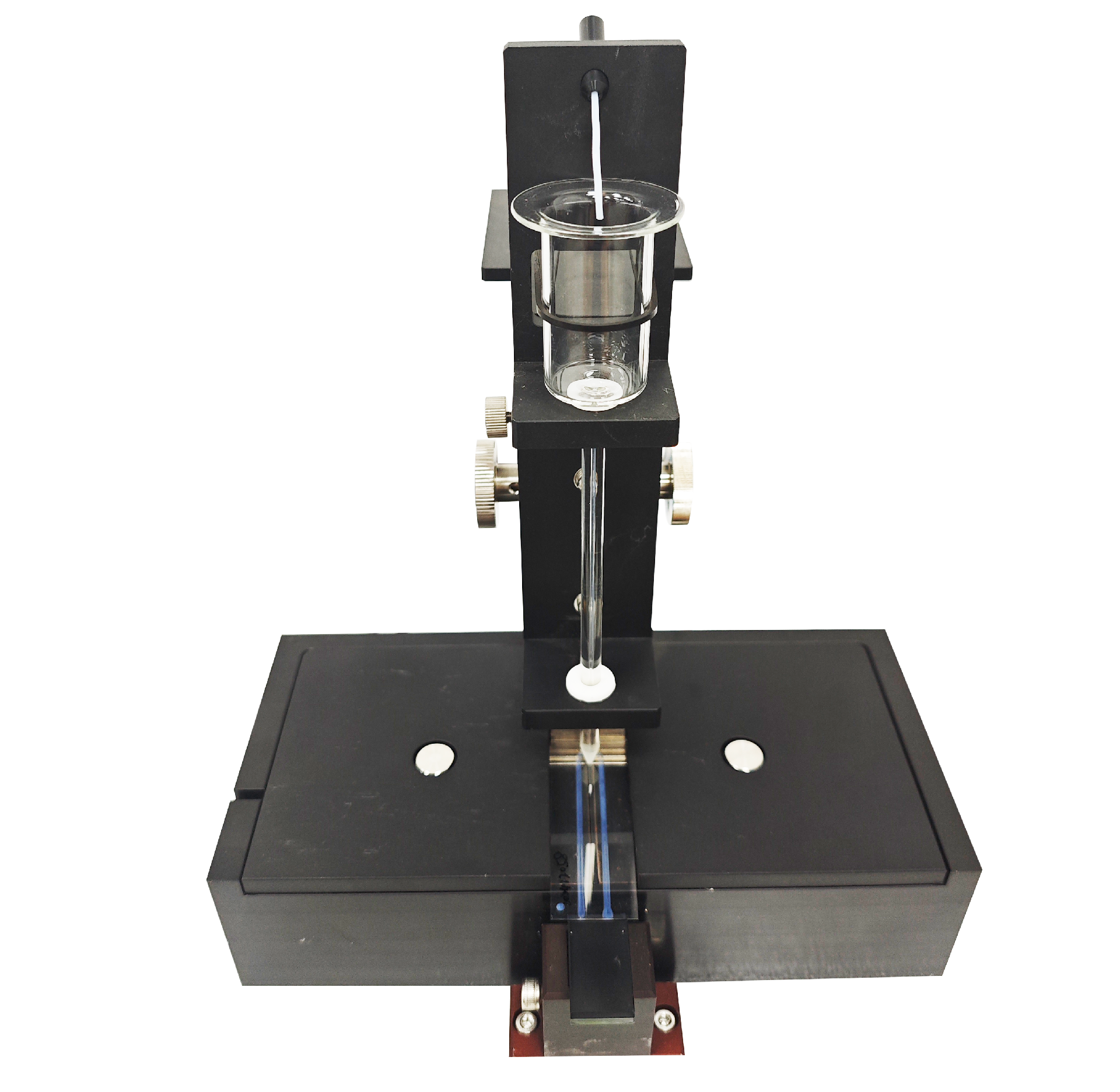

فيروسبكتومتر أنبوب ثيسل PJ500

رقم القطعة:

PJ500

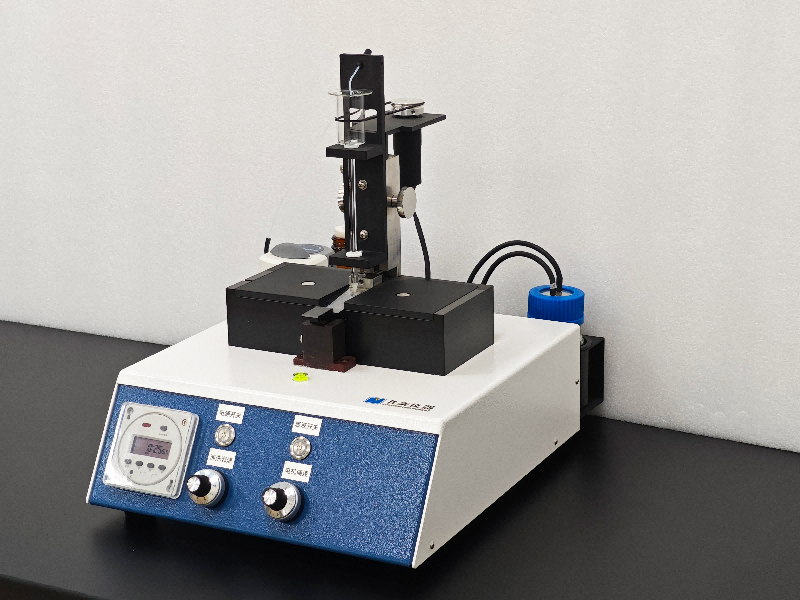

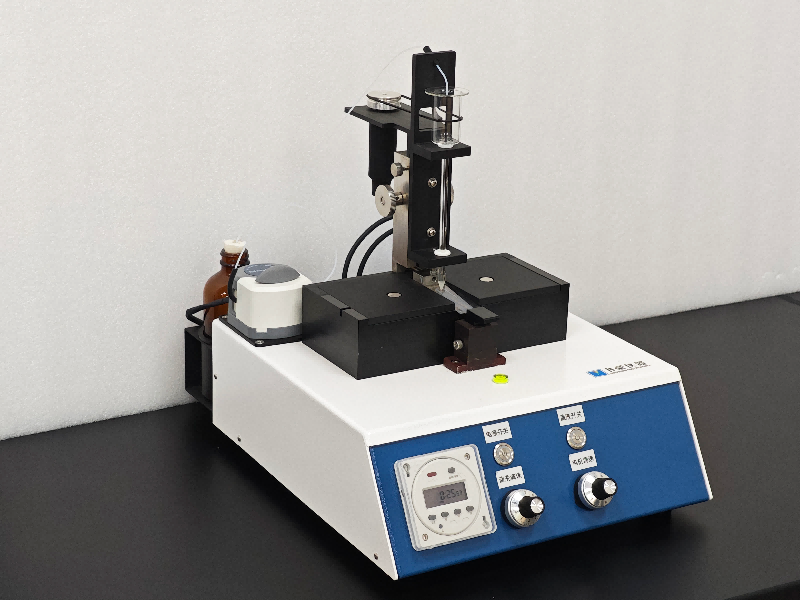

PJ500 هو محلل فيروغرافي محمول يعتمد على أنبوب "Thistle"، مصمم لفصل وتقييم جسيمات التآكل والملوثات في زيت التشحيم، السوائل الهيدروليكية، المبردات، أو الوقود. متوافق مع معايير ASTM D7690، D7684، و SH/T 0573‑1993، يترسب الجسيمات المغناطيسية على شريحة زجاجية بتدفق الجاذبية—محافظًا على شكل الجسيمات ويمنع التلف الناتج عن المضخات. مثالي للاستخدام الميداني والمخبري، ويضمن تحليلاً موثوقًا لجسيمات التآكل عبر مختلف الصناعات.

تدفق العينة المدفوع بالجاذبية

يتدفق الزيت بمعدل ~0.4 مل/دقيقة عبر أنبوب الشوك، مما يمنع التلف الناتج عن المضخة ويحافظ على سلامة الجسيمات.

مجال مغناطيسي عالي التدرج

يتميز بمغناطيس دائم قوي (~1.8 تسلا، تدرج >0.5 تسلا/سم) يضمن ترسبًا واضحًا وغير متداخل للجسيمات.

نطاق واسع لحجم الجسيمات

قادر على تحليل الجسيمات من 0-800 ميكرومتر، ويدعم تشخيصات التآكل الشاملة.

التنظيف الآلي ومعالجة الشرائح

يشتمل على تنظيف تلقائي موقوت، وتبادل سهل لأنابيب الشوك، وتحديد موضع ميداني قابل للتعديل لنتائج متسقة.

توفير المذيبات وسلامة المشغل

يتطلب عامل تنظيف أقل، مع تقليل المذيبات المبخرة للمخاطر الصحية؛ لا حاجة لغاز مضغوط خارجي.

تصميم محمول وقوي

مدمج (340 × 300 × 430 مم، ~9.6 كجم) ومناسب للبيئات الخارجية — يعمل بجهد 220 فولت/50 هرتز.

| المواصفة | القيمة |

|---|---|

| نطاق كشف الجسيمات | 0–800 ميكرومتر |

| معدل تدفق العينة | ~0.4 مل/دقيقة |

| حجم العينة | 2–3 مل لكل اختبار |

| شدة المجال المغناطيسي | ~1.8 تسلا تدرج >0.5 تسلا/سم |

| حجم الشريحة | 60 × 24 × 0.17 مم |

| الأبعاد (عرض × عمق × ارتفاع) | 340 × 300 × 430 مم |

| الوزن | حوالي 9.6 كجم |

| نظام التنظيف | آلي مع توقيت قابل للتعديل |

| شاشة العرض | 18–35 °م |

| نطاق درجة حرارة التشغيل | 18–35 °م |

| مزود الطاقة | تيار متردد 220 فولت ±10%، 50 هرتز |