Main

Uchambuzi wa Mafuta

Uchambuzi wa Chembe za Uchovu

Ferrograph ya uchambuzi wa mara mbili PA300

Nambari ya Sehemu:

PA300

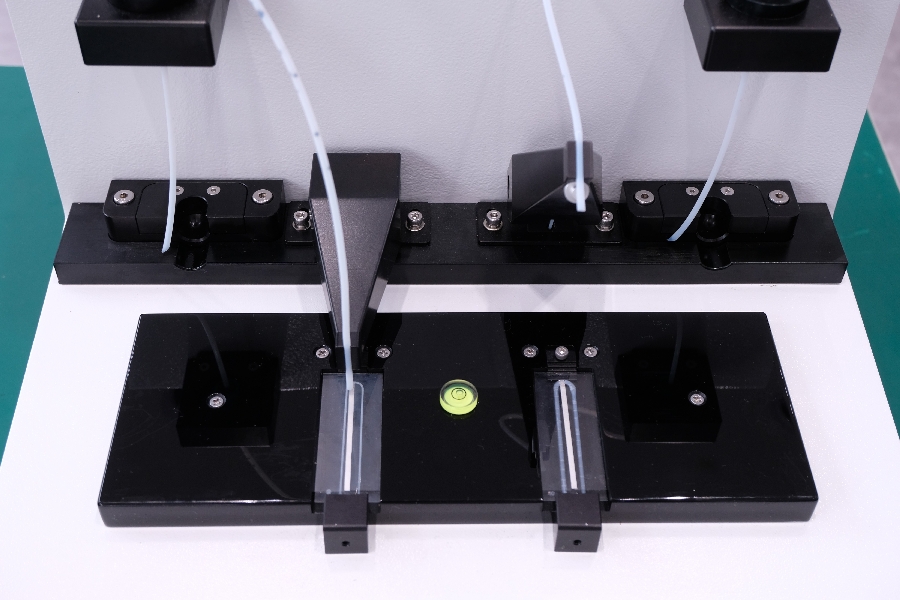

PA300 ni ferrograph ya benchi yenye modi mbili iliyoundwa kwa ajili ya tathmini kamili ya chembe za kuvaa katika mafuta ya kulainisha na vimiminika. Inachanganya ferrography endelevu ya kawaida (kwa uchambuzi wa umbo) na kipimo cha moja kwa moja cha sumaku, na kuwawezesha watumiaji kupata maelezo ya kuona ya kina na data ya nambari ya kuvaa katika mtiririko mmoja wa kazi uliorahisishwa—bora kwa matengenezo ya utabiri, uchunguzi wa mashine na ufuatiliaji wa hali.

Uchambuzi wa Njia Mbili

Huunganisha utayarishaji wa slaidi ya ferrogram (kwa ukaguzi wa kuona) na kukadiria chembe ya sumaku ya kiotomatiki, kutoa tathmini kamili ya uchakavu katika kukimbia moja.

Otomatiki & Rafiki kwa Mtumiaji

Sindano ya sampuli, uzalishaji wa slaidi, kukamata sumaku, na kuripoti data ni otomatiki kupitia skrini ya kugusa—na matokeo yanaweza kusafirishwa kupitia USB au Ethaneti.

Uwezo wa Ufuatiliaji wa Mwenendo

Programu iliyojengwa ndani huwezesha uwekaji wa data, kupanga, na arifa za kengele kugundua mifumo isiyo ya kawaida ya uchakavu mapema.

Uwanja wa Sumaku wa Gradient ya Juu

Udhibiti wa sumaku wa usahihi hutenga kwa ufanisi chembe za chuma kwa saizi na nguvu kwa uchambuzi sahihi.

Mahitaji Madogo ya Sampuli

Inahitaji tu 1-3 ml ya maji na inakamilisha njia zote mbili katika dakika 10-20, na kuifanya iwe na ufanisi mkubwa kwa matumizi ya kawaida ya maabara.

| Kipimo | Thamani |

|---|---|

| Kiasi cha sampuli | 1–3 mL kwa sampuli ya kimiminika |

| Jumla ya muda wa uchambuzi | ~10–20 dakika (utengenezaji wa slaidi na usomaji wa wingi) |

| Njia za uchambuzi wa chembe | Ubora (ferrogram ya darubini) + wingi (optical/magnetic) |

| Uzito wa uga wa sumaku | Gradient kubwa (~1.5 Tesla sawa) |

| Onyesho na kiolesura | Skrini ya kugusa, USB + Ethernet |

| Usimamizi wa data | Programu inawezesha uchambuzi wa mwenendo, hifadhi ya data, na kengele |

| Matumizi ya kimumunyisho | Tetrachloroethylene kwa kusafisha slaidi |

| Ukubwa na uzito | Muundo wa mezani compact |