Surface Treatment

Industry Overview

Key Features

Techniques vary depending on the substrate. Plasma and corona treatments introduce polar groups to polymer surfaces, increasing surface energy. Chemical etching removes oxides and contaminants from metals. Mechanical abrasion roughens surfaces to improve mechanical interlocking.

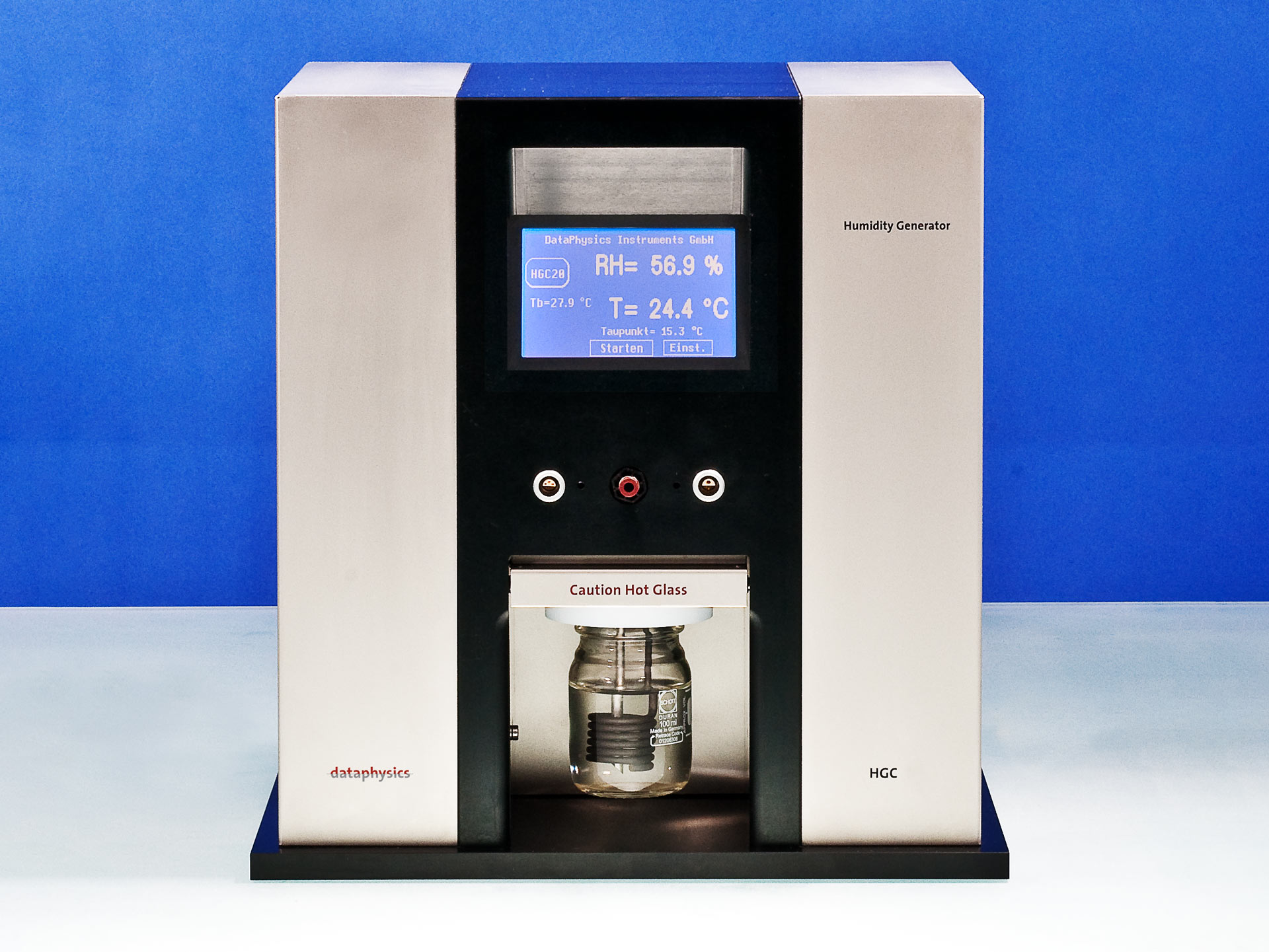

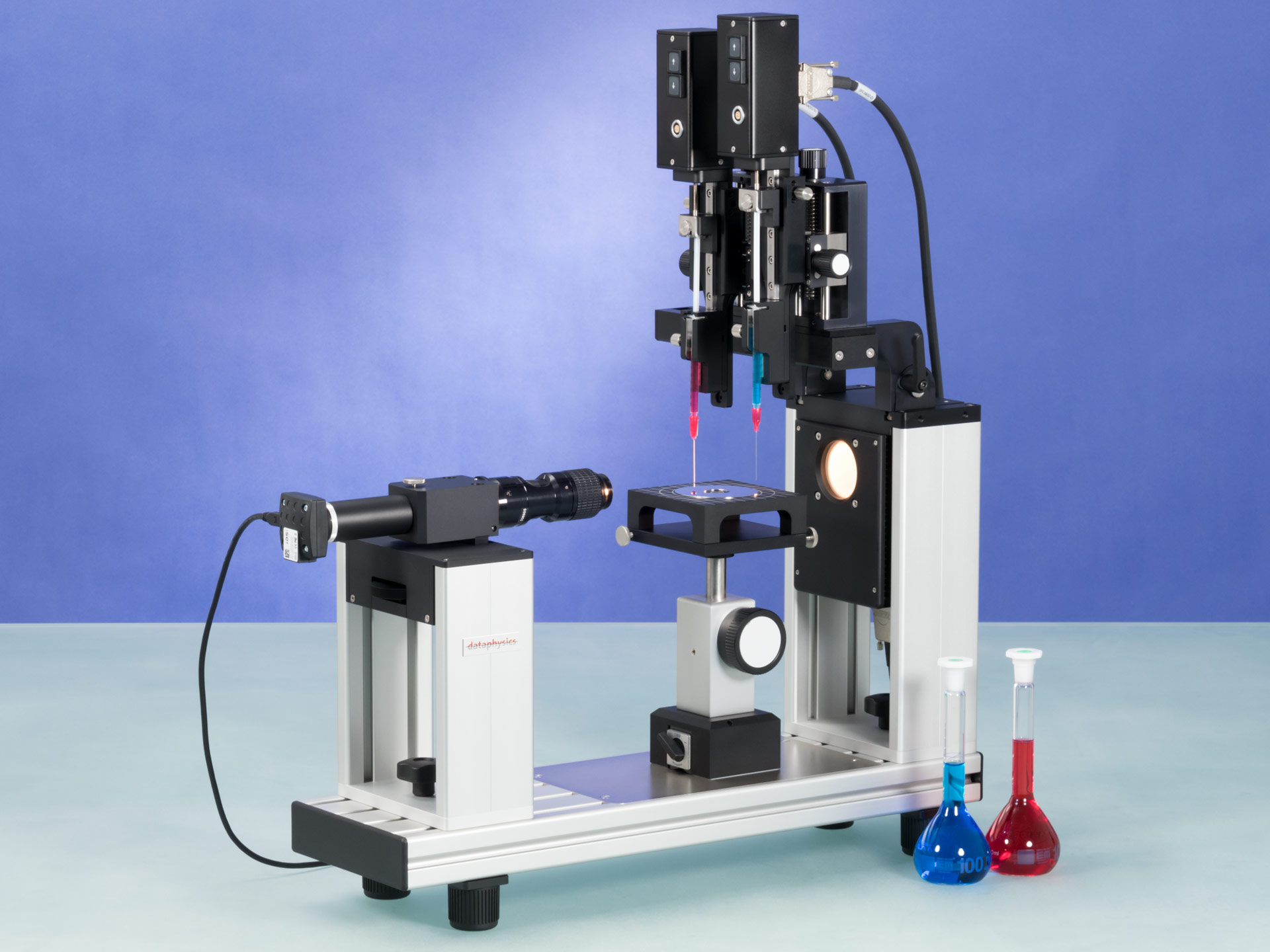

DataPhysics Instruments allow manufacturers to quantify these changes. The OCA series measures contact angles before and after treatment, providing direct evidence of improved wettability. The DCAT tensiometer evaluates surface tension and interfacial tension, offering insights into how treatments affect liquid-substrate interactions. The HGC humidity generator enables testing under controlled environmental conditions, ensuring treatments remain effective in real-world scenarios.

In R&D, these tools help optimize treatment parameters, such as plasma exposure time or chemical concentration. In production, they support quality assurance by providing reproducible, automated measurements that can be integrated into workflows. This ensures consistency across batches and compliance with industry standards.

Surface treatment is not just a preparatory step—it is a critical process that determines the success of coatings, adhesives, and printing. By providing precise, reproducible data, DataPhysics Instruments empower manufacturers to validate and optimize treatments, driving reliability and innovation.

Typical Tests & Applications

- Contact Angle Measurement (OCA)

- Purpose: Evaluate wettability improvements.

- Application: Compare surfaces before and after treatment.

- Benefit: Quantify treatment effectiveness.

- Surface Free Energy (OCA)

- Purpose: Determine energy components of treated surfaces.

- Application: Match substrates to coatings/adhesives.

- Benefit: Ensure optimal adhesion.

- Surface & Interfacial Tension (DCAT)

- Purpose: Assess liquid-substrate interactions.

- Application: Evaluate treatment impact on spreading behavior.

- Benefit: Improve coating uniformity.

- Dynamic Contact Angle & Hysteresis (OCA, DCAT)

- Purpose: Analyze advancing/receding angles.

- Application: Understand how treatments affect dynamic wetting.

- Benefit: Predict long-term adhesion performance.

- Environmental Testing (HGC)

- Purpose: Simulate humidity exposure.

- Application: Validate treatment durability under real-world conditions.

- Benefit: Ensure consistent performance.

These tests provide manufacturers with the data needed to validate and optimize surface treatments, ensuring reliable adhesion and long-term durability.

Industry Resources

No Resources Available

We're currently updating our resource library for this industry. Check back soon or contact us to request specific documentation.

Request DocumentationSupporting Products

Contact Angle & Surface Tension

Contact Angle & Surface Tension

DCAT – Dynamic Contact Angle measuring devices and Tensiometer

The versatile DCAT Series combines dynamic contact angle measuring devices and force tensiometers to...

Contact Angle & Surface Tension

Contact Angle & Surface Tension

HGC – Humidity Generator and Controller

The HGC Series offers standalone humidity generation and precision control (5 %–90 % RH) for s...

Oil Analysis

Oil Analysis

Intelligent Ferrography Lab (IFL-500 Series)

The Intelligent Ferrography Lab (IFL-500) is the world’s most advanced workstation for high-precis...

Contact Angle & Surface Tension

Contact Angle & Surface Tension

OCA – Optical contact angle measuring and contour analysis systems

The OCA Series by DataPhysics comprises high-precision optical contact angle goniometers and drop-sh...

Ready to Find the Right Solution?

Our team can help you select the perfect products for your Surface Treatment applications