PCB & Microfabrication

Industry Overview

Key Features

Surface properties play a pivotal role in PCB manufacturing. For example, solder mask adhesion depends on the wettability of the substrate. Poor adhesion can lead to delamination, corrosion, or electrical failure. Similarly, microfabrication processes require precise control of thin-film deposition, etching, and coating, all of which depend on surface energy and wettability.

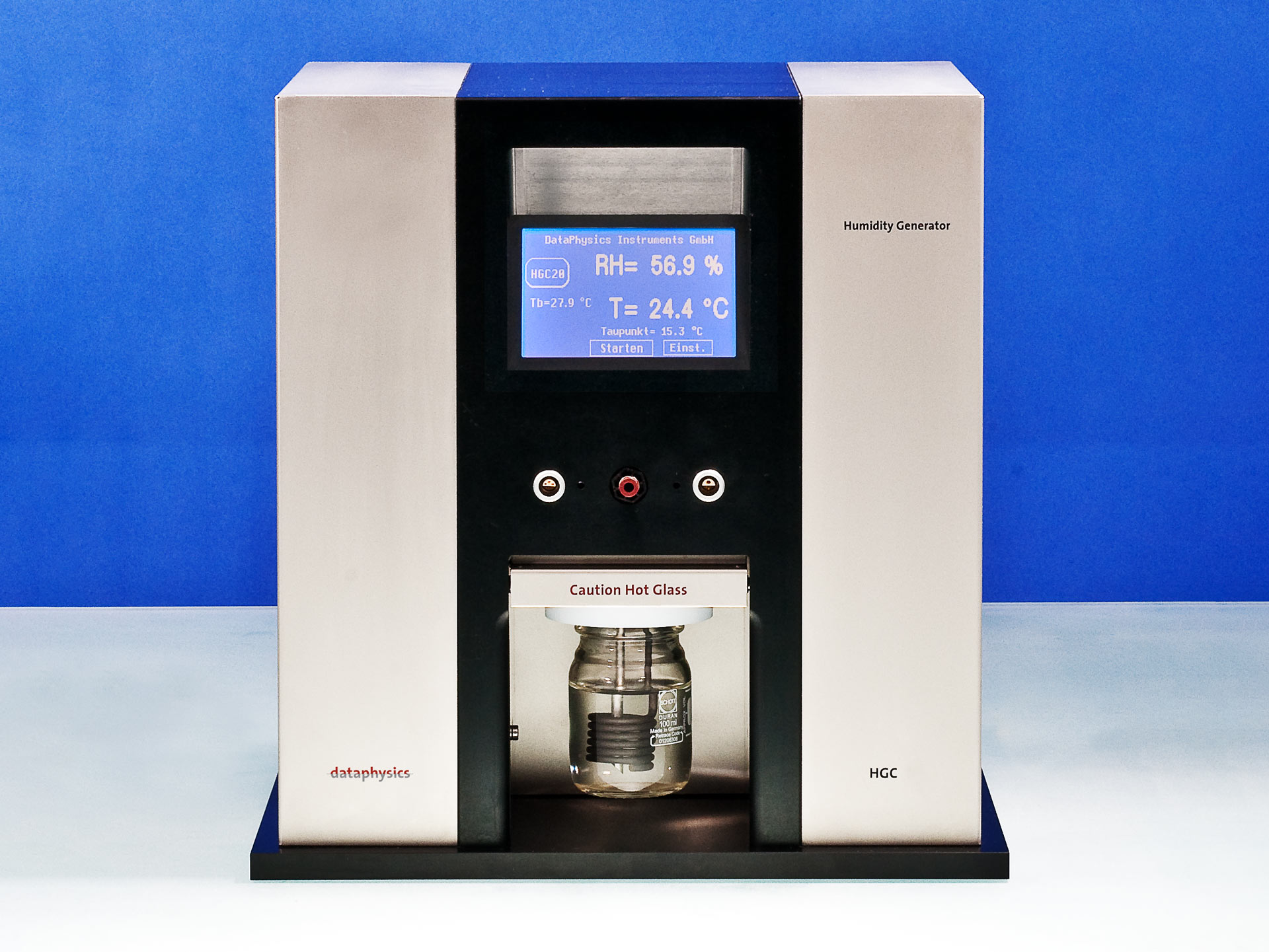

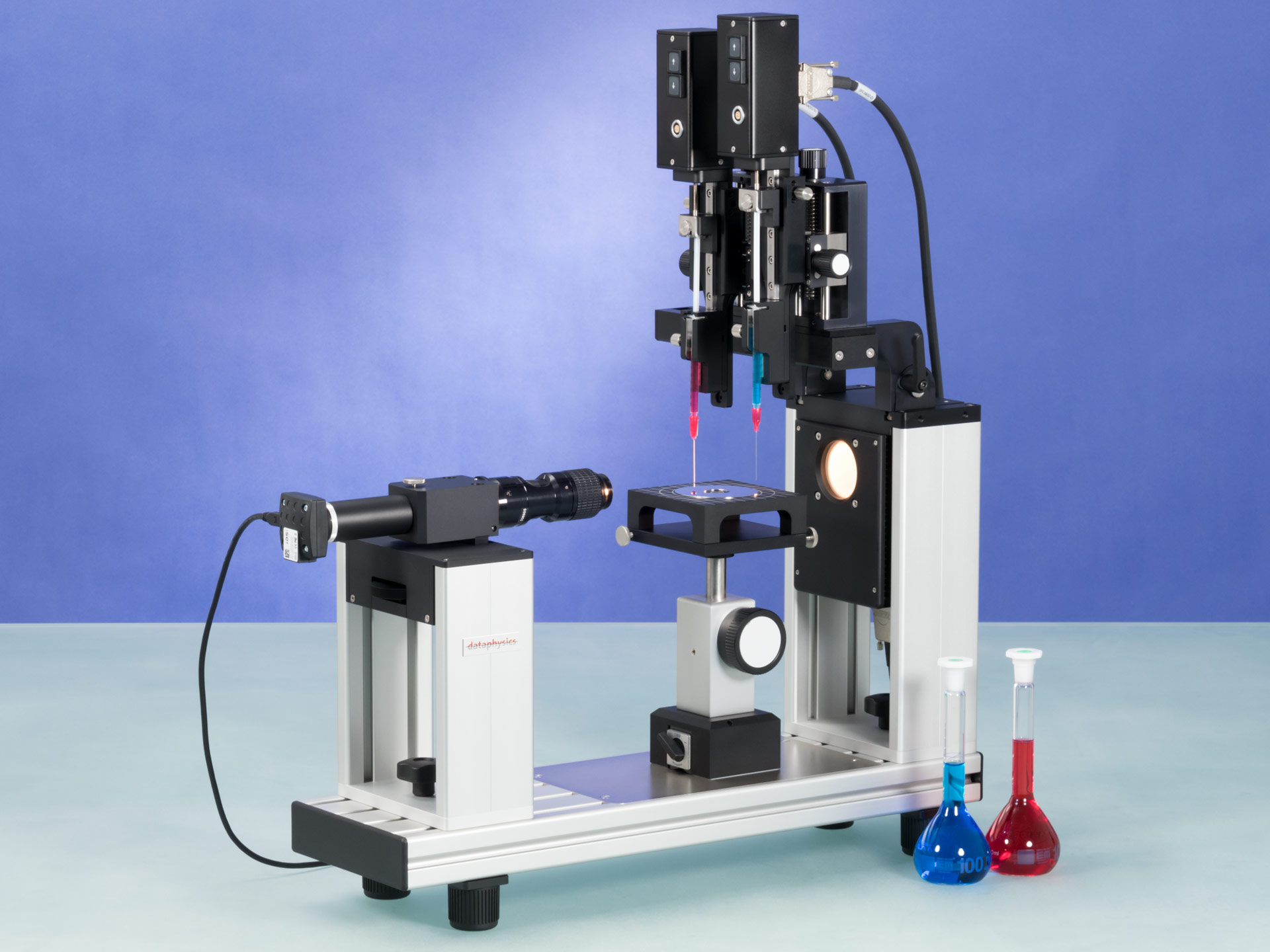

DataPhysics Instruments provide solutions to these challenges. The OCA series measures static and dynamic contact angles, offering insights into how coatings, adhesives, and solder masks interact with PCB substrates. The DCAT tensiometer evaluates surface and interfacial tension, helping engineers understand fluid-substrate compatibility. The HGC humidity generator simulates environmental conditions, allowing PCBs and microfabricated components to be tested under controlled humidity to predict real-world performance.

In R&D, these tools support the development of new materials and processes, enabling engineers to optimize adhesion, coating uniformity, and durability. In production, they support quality assurance by providing reproducible, automated measurements that ensure consistency across batches.

PCBs and microfabrication are not just about assembling electronics—they are about engineering precise interactions at the surface level. DataPhysics Instruments empower manufacturers to achieve this control, driving innovation and reliability in the electronics industry.

Typical Tests & Applications

- Contact Angle Measurement (OCA)

- Purpose: Assess wettability of substrates.

- Application: Predict adhesion of solder masks and coatings.

- Benefit: Prevent delamination and defects.

- Surface Free Energy (OCA)

- Purpose: Quantify substrate energy components.

- Application: Match coatings and adhesives to substrates.

- Benefit: Improve reliability and performance.

- Surface & Interfacial Tension (DCAT)

- Purpose: Evaluate fluid-substrate compatibility.

- Application: Optimize thin-film deposition and etching.

- Benefit: Enhance microfabrication precision.

- Dynamic Contact Angle & Hysteresis (OCA, DCAT)

- Purpose: Analyze advancing/receding angles.

- Application: Understand coating behavior under dynamic conditions.

- Benefit: Prevent defects in microfabricated structures.

- Humidity-Controlled Testing (HGC)

- Purpose: Simulate environmental exposure.

- Application: Test durability under varying humidity.

- Benefit: Predict long-term performance.

These tests provide engineers with actionable data to design reliable PCBs and microfabricated components, ensuring performance and durability in demanding applications.

Industry Resources

No Resources Available

We're currently updating our resource library for this industry. Check back soon or contact us to request specific documentation.

Request DocumentationSupporting Products

Contact Angle & Surface Tension

Contact Angle & Surface Tension

DCAT – Dynamic Contact Angle measuring devices and Tensiometer

The versatile DCAT Series combines dynamic contact angle measuring devices and force tensiometers to...

Contact Angle & Surface Tension

Contact Angle & Surface Tension

HGC – Humidity Generator and Controller

The HGC Series offers standalone humidity generation and precision control (5 %–90 % RH) for s...

Oil Analysis

Oil Analysis

Intelligent Ferrography Lab (IFL-500 Series)

The Intelligent Ferrography Lab (IFL-500) is the world’s most advanced workstation for high-precis...

Contact Angle & Surface Tension

Contact Angle & Surface Tension

OCA – Optical contact angle measuring and contour analysis systems

The OCA Series by DataPhysics comprises high-precision optical contact angle goniometers and drop-sh...

Ready to Find the Right Solution?

Our team can help you select the perfect products for your PCB & Microfabrication applications