Railways

Machine condition monitoring based on oil analysis has become an important, if not mandatory, maintenance practice by the transportation industry. An effective oil analysis program...

行业概览

Machine condition monitoring based on oil analysis has become an important, if not mandatory, maintenance practice by the transportation industry. An effective oil analysis program will keep important transportation industry assets such as engines in gearboxes in trains, buses and any other oil-wetted machinery in operation by reducing unexpected failures and costly unscheduled downtime.\r\n\r\n

主要特点

Machine condition monitoring based on oil analysis has become an important, if not mandatory, maintenance practice by the transportation industry. An effective oil analysis program will keep important transportation industry assets such as engines in gearboxes in trains, buses and any other oil-wetted machinery in operation by reducing unexpected failures and costly unscheduled downtime.

Challenges

Oil analysis for predictive monitoring was first used by the US railroad industry to monitor the health of locomotives. In 1946 the Denver and Rio Grande Railroad's research laboratory successfully detected diesel engine problems through wear metal analysis of used oils. The development of the spectrograph to detect individual metallic elements, such as copper and iron, was a key factor in their success. This practice was soon accepted and used extensively throughout the railroad industry.

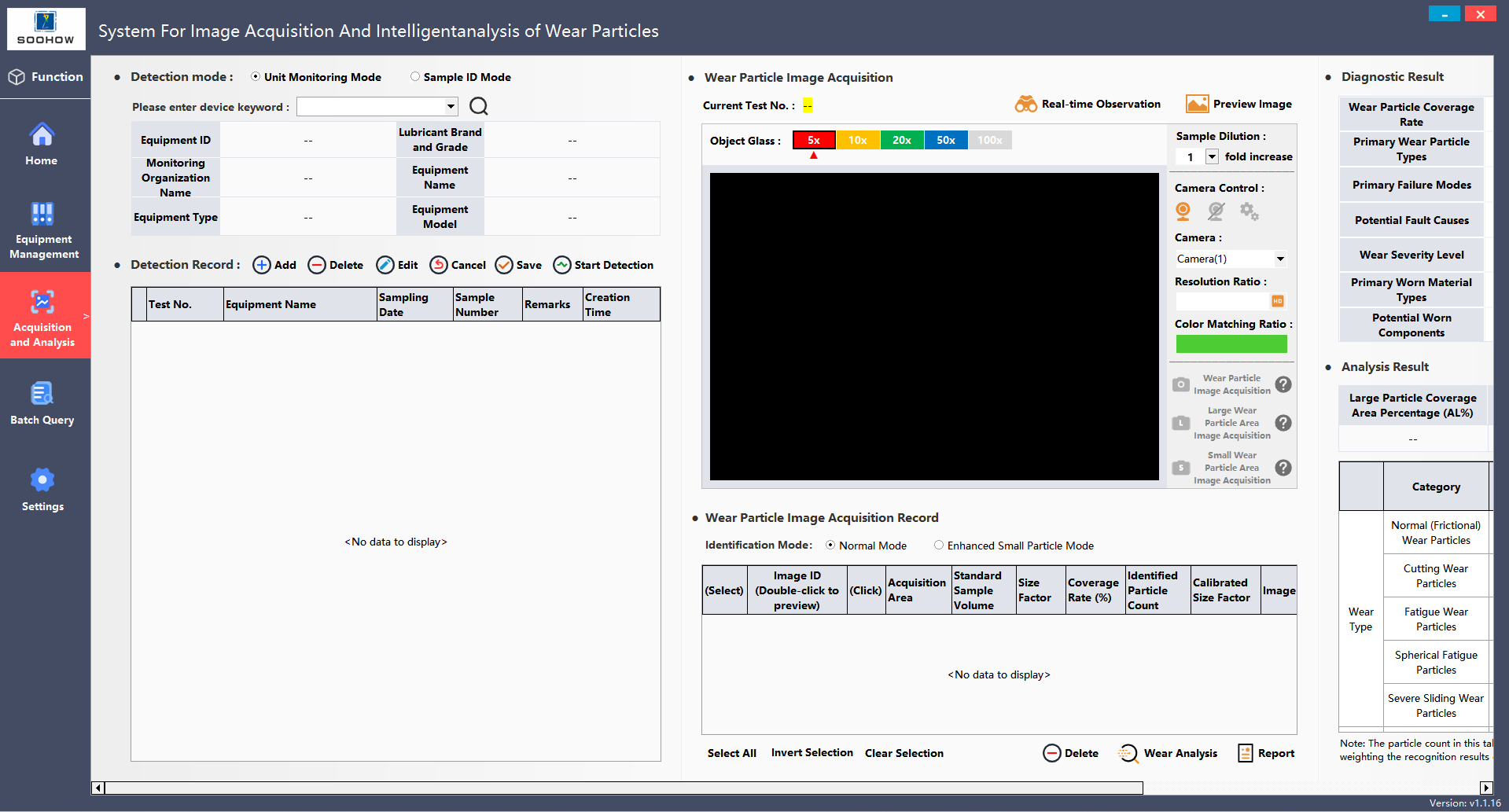

With such large equipment hauling heavy loads, wear is one of the critical measurements to monitor for predictive maintenance. A sudden increase in wear particles is typically indicative of an impending failure. Knowing the type of wear particles, sliding wear versus fatigue wear (for instance), also helps to determine the source of the particles.

Challenges

Oil analysis for predictive monitoring was first used by the US railroad industry to monitor the health of locomotives. In 1946 the Denver and Rio Grande Railroad's research laboratory successfully detected diesel engine problems through wear metal analysis of used oils. The development of the spectrograph to detect individual metallic elements, such as copper and iron, was a key factor in their success. This practice was soon accepted and used extensively throughout the railroad industry.

With such large equipment hauling heavy loads, wear is one of the critical measurements to monitor for predictive maintenance. A sudden increase in wear particles is typically indicative of an impending failure. Knowing the type of wear particles, sliding wear versus fatigue wear (for instance), also helps to determine the source of the particles.

典型测试与应用

Wear

Particle count - a high particle count or a rapid increase in particles can foreshadow an imminent failure.

Particle composition - it is often important to understand the elemental composition of particles in order to find out where they came from. Optical Emission Spectroscopy gives the user elemental information for up to 32 elements, from Li to Ce (varies with application).

Particle type - The size, shape and opacity of particles is used to determine if they are from cutting wear, sliding wear, fatigue wear, nonmetallic or fibers. This allows operators to determine the type of wear debris, wear mode and potential source from internal machinery components.

Ferrous wear - Ferrous wear measurement is a critical requirement for monitoring machine condition. The high sensitivity magnetometer measures and reports ferrous content in ppm/ml, and provides ferrous particle count and size distribution for large ferrous particles.

Particle count - a high particle count or a rapid increase in particles can foreshadow an imminent failure.

Particle composition - it is often important to understand the elemental composition of particles in order to find out where they came from. Optical Emission Spectroscopy gives the user elemental information for up to 32 elements, from Li to Ce (varies with application).

Particle type - The size, shape and opacity of particles is used to determine if they are from cutting wear, sliding wear, fatigue wear, nonmetallic or fibers. This allows operators to determine the type of wear debris, wear mode and potential source from internal machinery components.

Ferrous wear - Ferrous wear measurement is a critical requirement for monitoring machine condition. The high sensitivity magnetometer measures and reports ferrous content in ppm/ml, and provides ferrous particle count and size distribution for large ferrous particles.

行业资源

支持产品

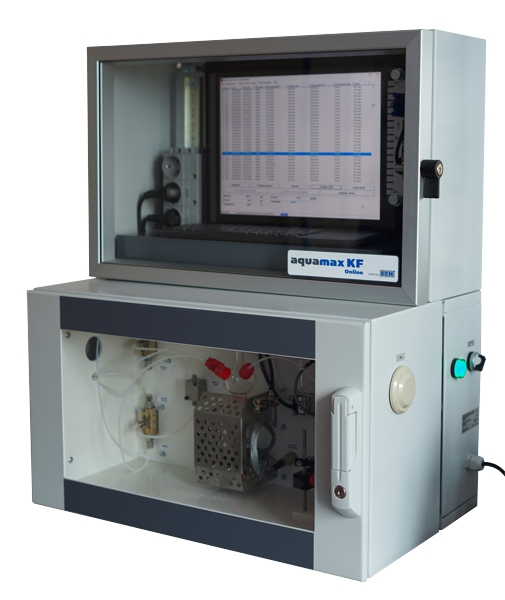

Oil Analysis

Oil Analysis

Oil Analysis

Oil Analysis

Oil Analysis

Oil Analysis

准备找到正确的解决方案?

我们的团队可以帮助您为您的应用选择完美的产品 Railways 应用