Main

Oil Analysis

Elemental Analysis

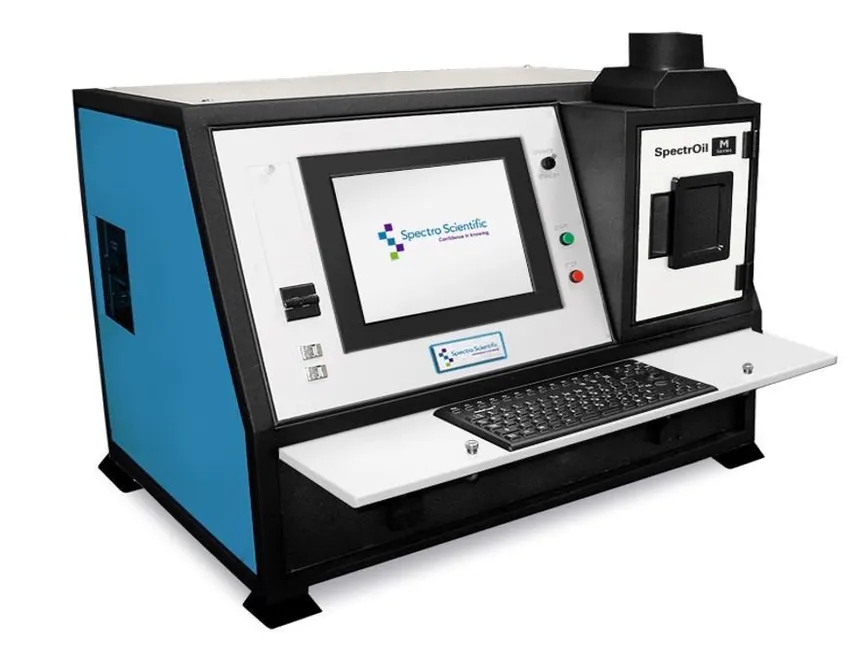

SpectrOil M Series

Part #:

M Series

The SpectrOil M Series is a compact, rugged, and highly reliable Rotating Disc Electrode Optical Emission Spectrometer (RDE‑OES) designed for accurate elemental analysis of lubricants, fuels, coolants, and water. Originally developed in the mid‑1990s for military use, it remains the only oil analysis spectrometer approved by the U.S. Department of Defense for the Joint Oil Analysis Program (JOAP). It delivers lab-grade performance in just 30 seconds, without the need for sample prep or solvents—ideal for deployment in extreme environments, mobile labs, and field service operations.

Military‑Hardened for Extreme Environments

Built to JOAP standards CID‑0191/486J, this series withstands shock, vibration, and extreme conditions—perfect for remote deployment on military vehicles, ships, and industrial sites.

Fast, Multi‑Element Results in 30 Seconds

Analyzes up to 31 elements simultaneously with sub‑ppm sensitivity, providing critical wear, additive, and contaminant data in half a minute.

No Sample Prep – Direct, Hassle‑Free Testing

Simply add ~2 mL of fluid—no dilution, no solvents, no gases. This ensures quick, field-ready analysis with minimal consumables.

Versatile Calibration Profiles for Various Fluids

Choose models tailored to your needs:

M/C‑W: Commercial oil & hydraulic fluids (24 elements).

M/F‑W: Light and heavy fuels (15 elements).

M/F‑LD: Low-detection diesel (V ≤ 0.1 ppm).

M/N‑W: JOAP military oil analysis (15 elements).

M/C‑W: Commercial oil & hydraulic fluids (24 elements).

M/F‑W: Light and heavy fuels (15 elements).

M/F‑LD: Low-detection diesel (V ≤ 0.1 ppm).

M/N‑W: JOAP military oil analysis (15 elements).

User‑Friendly with Built‑In Touch‑Panel and Software

Integrated rugged touch-panel PC allows simple operation with no specialized training. Supports rapid switching between fluid types via preloaded calibration packs.

Standards-Compliant for Oil & Fuel Testing

Certified to meet ASTM D6595 (lubricants) and ASTM D6728 (fuels), as well as JOAP, ensuring globally recognized accuracy.

Optional Robotics for Unattended Operation (M/R)

Models with the Double Disc Rapid Robot (D2R2) enable fully automated sample handling and electrode replacement for high-throughput analysis (~50 samples).

| Specification | Value |

|---|---|

| Detection Method | RDE OES (Rotating Disc Electrode – Optical Emission Spectrometry) |

| Element Range | Up to 31 elements (wear, additives, contaminants) |

| Sample Volume | ~2 mL |

| Analysis Time | ~30 seconds |

| Detection Limit | Sub ppm levels |

| Sample Prep | None required |

| Calibration Options | Fluid-specific (oil, fuel, coolant, military) |

| Certifications | ASTM D6595, ASTM D6728, JOAP CID 0191/486J |

| Dimensions (WxDxH) | 80 × 63.5 × 70 cm |

| Weight | 114–132 kg depending on model |

| Power | AC 110/220 V, 50/60 Hz |

| User Interface | Built-in industrial touch-panel PC |

| Optional Robotics | D2R2 automated sample changer |