Emulsions & Sauces

Food & Beverage Sector

Emulsions & Sauces are complex food systems where immiscible liquids, typically oil and water, are stabilized by emulsifiers to form a uniform product. They are fundamental in culi...

Industry Overview

Emulsions & Sauces are complex food systems where immiscible liquids, typically oil and water, are stabilized by emulsifiers to form a uniform product. They are fundamental in culinary and industrial food production, appearing in mayonnaise, salad dressings, ketchup, and creamy sauces. The stability of these emulsions determines texture, taste, shelf life, and consumer satisfaction. DataPhysics Instruments provide advanced tools to measure dispersion stability, interfacial tension, and particle interactions, enabling food technologists to design sauces that remain homogeneous, appealing, and safe throughout storage and consumption.

Key Features

Emulsions are heterogeneous mixtures where droplets of one liquid are dispersed in another. In food, oil-in-water emulsions dominate, stabilized by surfactants or proteins. Sauces like mayonnaise, hollandaise, and salad dressings rely on stable emulsions to deliver creamy textures and consistent flavor.

Challenges in emulsions include phase separation, creaming, and coalescence. These phenomena occur when droplets aggregate or rise to the surface, leading to visible separation and loss of quality. Stability depends on droplet size, interfacial tension, viscosity, and the presence of stabilizers.

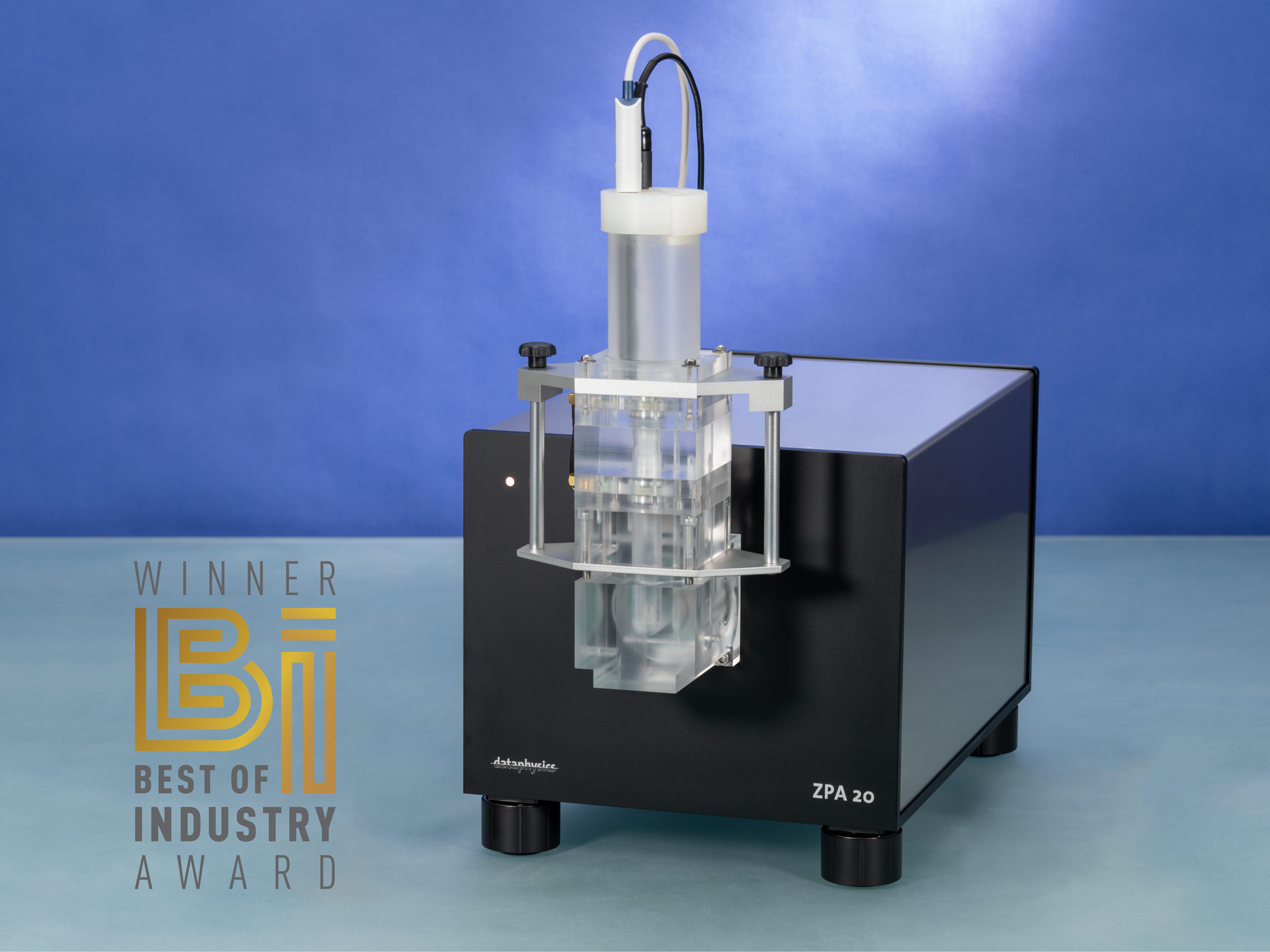

DataPhysics Instruments address these challenges with precision. The MultiScan system monitors emulsions over time, detecting early signs of instability such as creaming or sedimentation. The ZPA 20 measures zeta potential, indicating the electrostatic repulsion between droplets. High zeta potential values suggest strong stability, while low values indicate risk of aggregation. The DCAT tensiometer measures interfacial tension, helping formulators understand how emulsifiers reduce tension to stabilize droplets.

In R&D, these tools allow food scientists to optimize emulsifier concentration, droplet size, and viscosity. In production, they support quality assurance by providing reproducible, automated measurements that ensure batch-to-batch consistency.

Emulsions & Sauces are not just culinary products—they are engineered systems requiring precise control of colloidal and interfacial properties. DataPhysics Instruments empower food technologists to achieve this control, driving innovation and consumer satisfaction.

Challenges in emulsions include phase separation, creaming, and coalescence. These phenomena occur when droplets aggregate or rise to the surface, leading to visible separation and loss of quality. Stability depends on droplet size, interfacial tension, viscosity, and the presence of stabilizers.

DataPhysics Instruments address these challenges with precision. The MultiScan system monitors emulsions over time, detecting early signs of instability such as creaming or sedimentation. The ZPA 20 measures zeta potential, indicating the electrostatic repulsion between droplets. High zeta potential values suggest strong stability, while low values indicate risk of aggregation. The DCAT tensiometer measures interfacial tension, helping formulators understand how emulsifiers reduce tension to stabilize droplets.

In R&D, these tools allow food scientists to optimize emulsifier concentration, droplet size, and viscosity. In production, they support quality assurance by providing reproducible, automated measurements that ensure batch-to-batch consistency.

Emulsions & Sauces are not just culinary products—they are engineered systems requiring precise control of colloidal and interfacial properties. DataPhysics Instruments empower food technologists to achieve this control, driving innovation and consumer satisfaction.

Typical Tests & Applications

Key tests for Emulsions & Sauces include:

- Dispersion Stability Monitoring (MultiScan)

- Purpose: Track emulsion behavior over time.

- Application: Detect creaming, coalescence, or phase separation.

- Benefit: Ensure long shelf life and consistent texture.

- Zeta Potential Measurement (ZPA 20)

- Purpose: Assess droplet surface charge.

- Application: Predict emulsion stability.

- Benefit: Optimize emulsifier use.

- Interfacial Tension Measurement (DCAT)

- Purpose: Evaluate emulsifier effectiveness.

- Application: Reduce droplet aggregation.

- Benefit: Improve homogeneity and mouthfeel.

- Dynamic Contact Angle Analysis (OCA, DCAT)

- Purpose: Study droplet wetting in continuous phase.

- Application: Enhance dispersion.

- Benefit: Prevent clumping and separation.

- Environmental Simulation (HGC)

- Purpose: Test stability under humidity and temperature changes.

- Application: Validate storage conditions.

- Benefit: Ensure product reliability.

These tests provide food technologists with actionable data to design stable, appealing sauces and emulsions.

- Dispersion Stability Monitoring (MultiScan)

- Purpose: Track emulsion behavior over time.

- Application: Detect creaming, coalescence, or phase separation.

- Benefit: Ensure long shelf life and consistent texture.

- Zeta Potential Measurement (ZPA 20)

- Purpose: Assess droplet surface charge.

- Application: Predict emulsion stability.

- Benefit: Optimize emulsifier use.

- Interfacial Tension Measurement (DCAT)

- Purpose: Evaluate emulsifier effectiveness.

- Application: Reduce droplet aggregation.

- Benefit: Improve homogeneity and mouthfeel.

- Dynamic Contact Angle Analysis (OCA, DCAT)

- Purpose: Study droplet wetting in continuous phase.

- Application: Enhance dispersion.

- Benefit: Prevent clumping and separation.

- Environmental Simulation (HGC)

- Purpose: Test stability under humidity and temperature changes.

- Application: Validate storage conditions.

- Benefit: Ensure product reliability.

These tests provide food technologists with actionable data to design stable, appealing sauces and emulsions.

Industry Resources

No Resources Available

We're currently updating our resource library for this industry. Check back soon or contact us to request specific documentation.

Request DocumentationSupporting Products

Contact Angle & Surface Tension

Contact Angle & Surface Tension

MS – MultiScan dispersion stability analysis system

Part #: MS

The MultiScan MS 20 is an advanced optical analyzer designed for automatic, time- and temperature-...

Contact Angle & Surface Tension

Contact Angle & Surface Tension

SVT – Spinning drop Video Tensiometer

Part #: SVT

The SVT 25 is a specialized optical instrument for measuring ultra-low interfacial tensions and dy...

Contact Angle & Surface Tension

Contact Angle & Surface Tension

ZPA – Zeta Potential Analyzer

Part #: ZPA

The ZPA 20 is a compact, high-precision instrument that measures surface zeta potential of macrosc...

Ready to Find the Right Solution?

Our team can help you select the perfect products for your Emulsions & Sauces applications