Main

Oil Analysis

Particle Counter

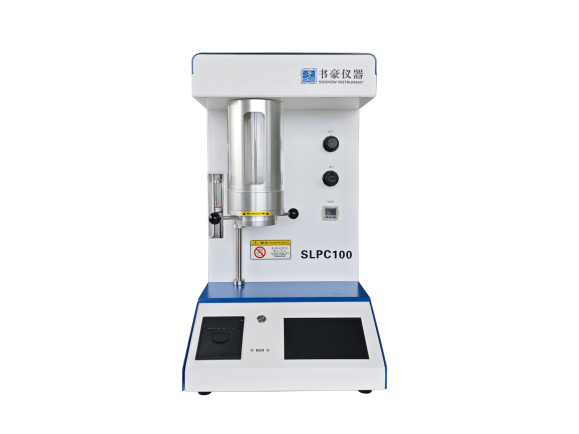

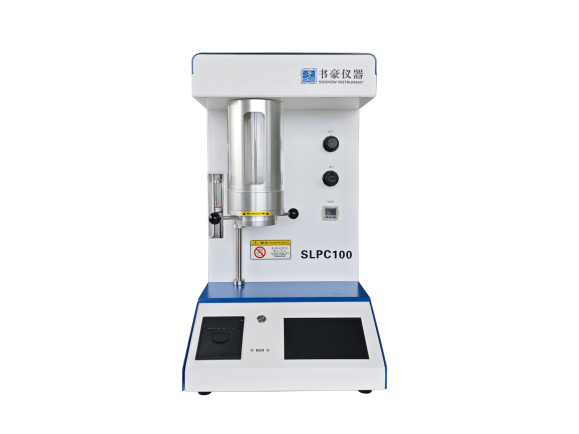

SLPC100 Desktop Oil Particle Counter

Part #:

SLPC100

The SLPC100 is a desktop oil particle counter that employs the internationally recognized light obscuration counting method. Engineered to meet military, national, and international standards, it features a high-precision laser sensor, broad measurement range, and excellent stability. With support for multiple sampling methods and built-in calibration curves, the SLPC100 provides fast, reliable, repeatable contamination analysis for a wide range of industries including aviation, aerospace, power generation, chemical, transportation, and manufacturing.

Compact Desktop Design with Industrial-Grade Performance

The SLPC100 is built as a space-saving desktop unit, ideal for laboratories and maintenance centers that require high-accuracy oil particle analysis without occupying much space. Despite its compact size, it delivers powerful industrial performance, ensuring stable operation and repeatable results even under demanding usage conditions.

Advanced Laser Sensing with 32 High-Resolution Channels

At the heart of the SLPC100 is a high-precision laser sensor capable of detecting particles across 32 resolution channels. This allows for precise measurement and classification of particles ranging from fine debris to large contamination, providing detailed insight into oil cleanliness and wear conditions.

Compliant with Global Particle Counting Standards

The system is factory-calibrated to meet international calibration standards including ISO 4402, ISO 11171, and GB/T 18854. These certifications ensure reliable and globally accepted results, making it a trusted tool for quality assurance, reliability, and regulatory compliance across sectors.

Multiple Sampling Modes for Flexible Operation

The SLPC100 supports various sampling techniques, including manual syringe sampling, pressurized online sampling, or automated flow paths. This flexibility allows users to analyze a broad range of fluid systems—whether in a lab or connected directly to live equipment.

Rapid and Repeatable Testing

Engineered for high throughput and reliability, the SLPC100 delivers results in a matter of minutes. Its stable measurement system ensures that repeated tests yield highly consistent data, critical for trend analysis and maintenance planning.

Industry-Wide Application Versatility

From aviation and aerospace to energy, chemicals, transportation, and heavy industry, the SLPC100 is designed to support fluid cleanliness monitoring in a wide range of fields. Its adaptability and accuracy make it a valuable asset for quality control, preventive maintenance, and fluid management programs.

| Specification | Value |

|---|---|

| Detection Method | Light obscuration (optical particle counting) |

| Detection Channels | 32 channels with high-resolution measurement |

| Calibration Standards | ISO 4402, ISO 11171, GB/T 18854 |

| Sampling Methods | Multiple selectable modes (manual syringe, pressurized line, etc.) |

| Supported Fluids | Hydraulic oils, lubricants, turbine oil, gear oil, transformer oil |

| Output Data | Particle size/count, ISO cleanliness codes, contamination analysis reports |

| Accuracy & Repeatability | Factory-calibrated; consistent test results |

| Operating Environment | Laboratory / Industrial setting |

| Suitable Industries | Aviation, aerospace, energy, chemical, transportation, heavy manufacturing, etc. |

| Dimensions & Footprint | Desktop form factor—compact enough for bench-top installation |

4564