Oil & Gas Exploration

Industry Overview

Key Features

Challenges

Oil exploration is often done in remote locations, making the use of off-site oil analysis laboratories impractical. Off shore oil rigs are a perfect example. By the time an oil sample is taken, sent ashore, analyzed the results returned to the rig, weeks may have passed. In that time a critical piece of equipment could fail.

Bringing oil analysis on-site greatly reduces cost of analysis and improves predictive maintenance.

The same logic applies when testing produced water. On-site analysis provides actionable results quickly, allowing operators to know if their results are meeting regulatory requirements.

Typical Tests & Applications

Particle count - a high particle count or a rapid increase in particles can foreshadow an imminent failure.

Particle composition - it is often important to understand the elemental composition of particles in order to find out where they came from. Optical Emission Spectroscopy gives the user elemental information for up to 32 elements, from Li to Ce (varies with application).

Particle type - The size, shape and opacity of particles is used to determine if they are from cutting wear, sliding wear, fatigue wear, nonmetallic or fibers. This allows operators to determine the type of wear debris, wear mode and potential source from internal machinery components.

Ferrous wear - Ferrous wear measurement is a critical requirement for monitoring machine condition. The high sensitivity magnetometer measures and reports ferrous content in ppm/ml, and provides ferrous particle count and size distribution for large ferrous particles.

Chemistry

Total Acid Number (TAN) - TAN is measured to determine the corrosive potential of lubrication oils. If the TAN gets too high the oil can induce corrosion of machine parts and should be changed.

Total Base Number (TBN) - TBN measures the amount of active additive left in a sample of oil. The TBN is useful for people who want to extend their oil usage far beyond the normal range. The TBN of a used oil can aid the user in determining how much reserve additive the oil has left to neutralize acids. The lower the TBN reading, the less active additive the oil has left.

Viscosity - The main function of lubrication oil is to create and maintain a lubrication film between two moving metal surfaces. Insuring the viscosity is within recommended ranges is one of the most important tests one can run on lube oil.

Contamination

Fuel Dilution - Fuel dilution in oil is a condition caused by excess, unburned fuel mixing with engine oil in an engine crankcase. Hydrocarbon-based fuel, usually with a lower vapor pressure than the lubricant, has a thinning effect, lowering the oil viscosity. Oil film strength is reduced, increasing the cylinder liner and bearing wear.

Soot - Soot is a product of combustion and has always been found in engine oils. Soot can use up an oil's additives and deposit on vital engine surfaces.

Glycol - Glycol is found in engine coolant. If glycol is found in engine oil it typically indicates there is a leak in the engine that can cause catastrophic damage to the cylinder or cylinder wall.

Water - Water contamination in industrial oils can cause severe issues with machinery components. The presence of water can alter the viscosity of a lubricant as well as cause chemical changes resulting in additive depletion and the formation of acids, sludge, and varnish.

Produced Water

Complies with ASTM D7066, EPA 413.2 & 418.1

Compares with EPA 1664

Detect levels as low as 0.1 mg/L

Unlike UV, measures aromatic and aliphatic hydrocarbons

Two InfraCal Analyzers suitable for this application

Industry Resources

No Resources Available

We're currently updating our resource library for this industry. Check back soon or contact us to request specific documentation.

Request DocumentationSupporting Products

Oil Analysis

Oil Analysis

MiniVisc 3000

The MiniVisc 3000 is a groundbreaking portable kinematic viscometer that delivers laboratory-grade v...

Oil Analysis

Oil Analysis

Pi Raptor Portable

The Raptor Portable Dry Powder Particle Size & Shape Analyzer is the first truly portable system tha...

Oil Analysis

Oil Analysis

Pi Sentinel PRO

The SentinelPro is a high-performance dynamic image analyzer designed for applications where particl...

Oil Analysis

Oil Analysis

Portable Kinematic Viscometer VS800

The VS800 Portable Kinematic Viscometer is a precision, multi-purpose viscosity measurement tool des...

Oil Analysis

Oil Analysis

R4 RotrOil (Automatic Sample Changer)

The R4 RotrOil is an advanced, fully automated version of GNR's RotrOil elemental spectrometer. It i...

Oil Analysis

Oil Analysis

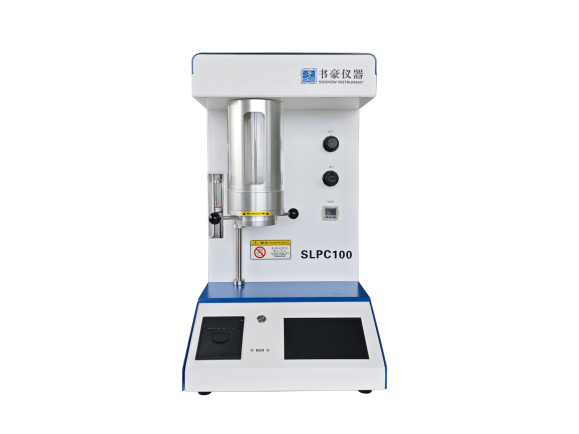

SLPC100 Desktop Oil Particle Counter

The SLPC100 is a desktop oil particle counter that employs the internationally recognized light obsc...

Oil Analysis

Oil Analysis

SpectrOil 100 Series

The SpectrOil 100 Series is a high-precision elemental analyzer based on Rotating Disc Electrode Opt...

Ready to Find the Right Solution?

Our team can help you select the perfect products for your Oil & Gas Exploration applications