Cat & Pelapis (Coating)

Ikhtisar Industri

Fitur Utama

The science behind coatings revolves around surface interactions. For a coating to adhere properly, it must wet the substrate effectively. Wettability is influenced by the surface energy of the substrate and the surface tension of the coating formulation. If the coating fails to wet, defects such as peeling, blistering, or poor coverage occur.

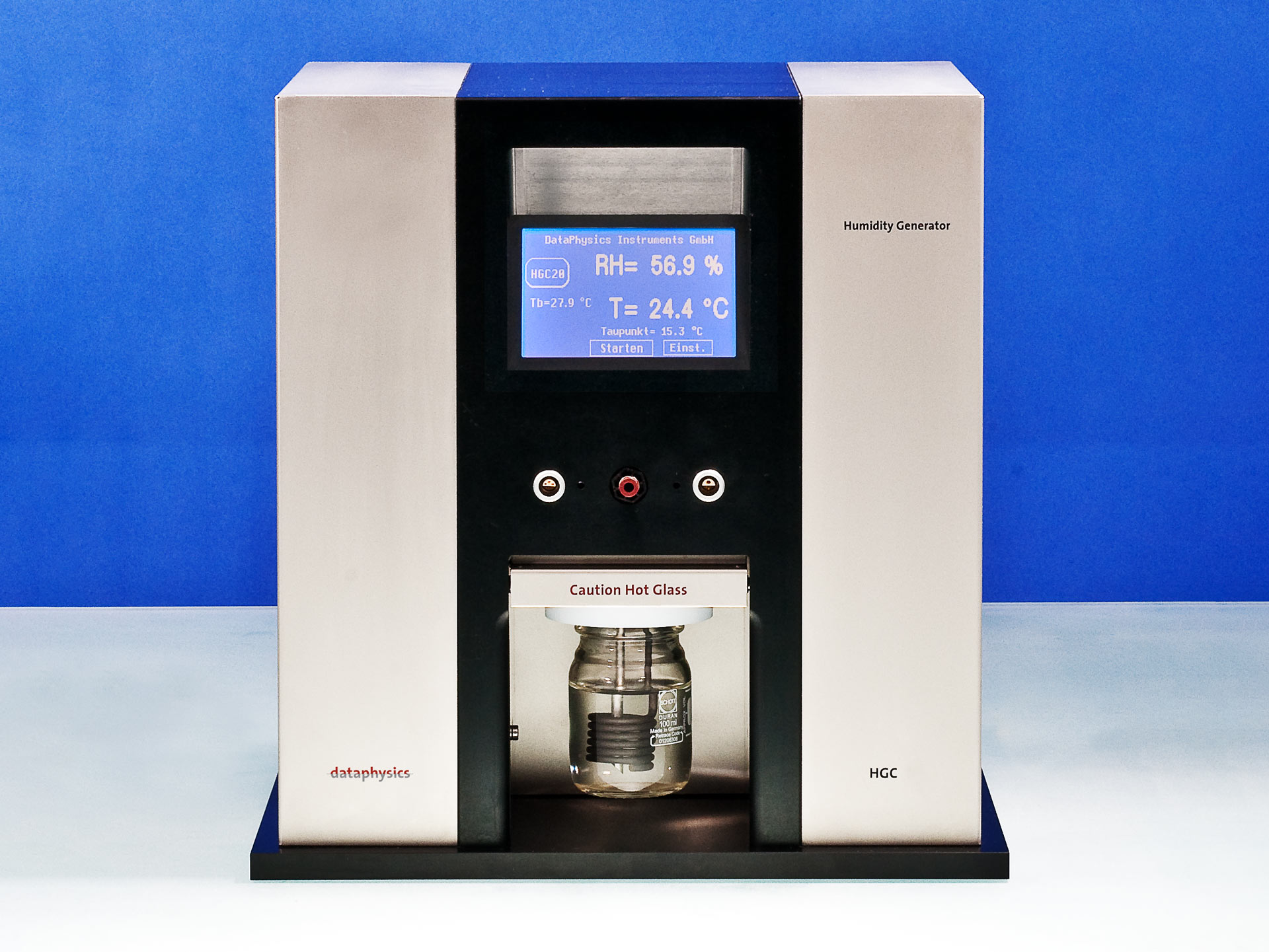

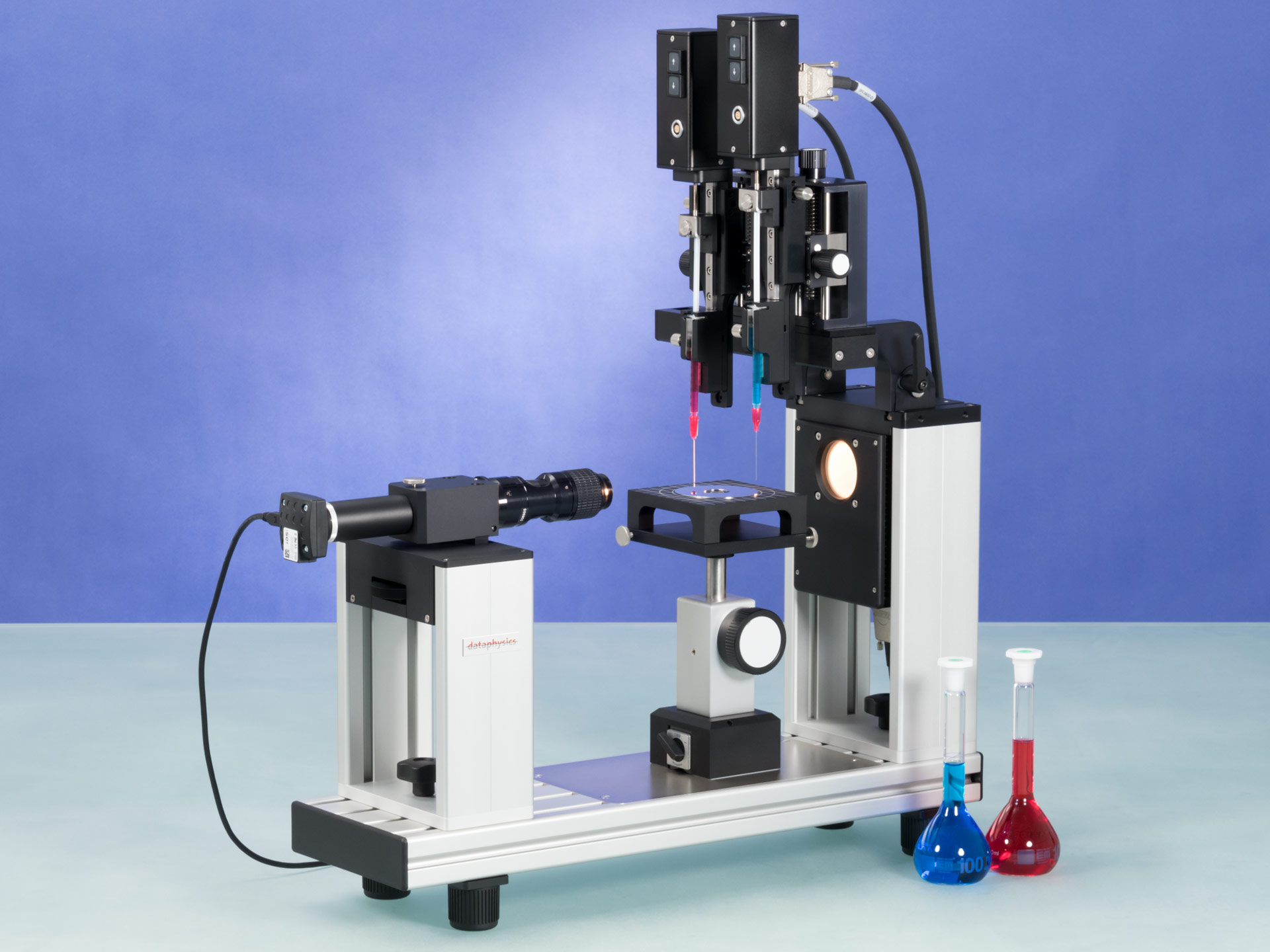

DataPhysics Instruments address these challenges with precision. The OCA series measures static and dynamic contact angles, providing insights into how coatings spread and adhere. The DCAT tensiometer evaluates surface and interfacial tension, crucial for understanding paint-substrate compatibility. The HGC humidity generator simulates environmental conditions, allowing coatings to be tested under controlled humidity to predict real-world performance.

Surface preparation is equally important. Substrates may undergo plasma treatment, chemical cleaning, or mechanical abrasion to increase surface energy. DataPhysics devices quantify the effectiveness of these treatments by comparing contact angle and surface energy values before and after.

In R&D, these tools help optimize formulations by balancing viscosity, flow, and curing properties. They also support quality assurance by providing reproducible, automated measurements that can be integrated into production workflows. This reduces variability, enhances reliability, and ensures compliance with industry standards.

Ultimately, paints & coatings are more than just decorative layers—they are engineered systems whose success depends on precise control of surface and interfacial properties. DataPhysics Instruments empower manufacturers to achieve this control, driving innovation and quality across industries.

Tes & Aplikasi Khas

- Contact Angle Measurement (OCA)

- Purpose: Assess coating wettability on substrates.

- Application: Predict adhesion and coverage quality.

- Benefit: Optimize surface preparation and reduce defects.

- Surface Free Energy (OCA)

- Purpose: Quantify substrate energy components.

- Application: Match coatings to substrates for maximum adhesion.

- Benefit: Reduce trial-and-error in formulation.

- Surface & Interfacial Tension (DCAT)

- Purpose: Measure coating-liquid interactions.

- Application: Evaluate spreading and leveling behavior.

- Benefit: Improve uniformity and finish quality.

- Humidity-Controlled Testing (HGC)

- Purpose: Simulate environmental exposure.

- Application: Test coating durability under varying humidity.

- Benefit: Predict long-term performance.

- Dynamic Contact Angle & Hysteresis (OCA, DCAT)

- Purpose: Analyze advancing/receding angles.

- Application: Understand coating behavior under dynamic conditions.

- Benefit: Prevent peeling and blistering.

These tests provide actionable insights that help manufacturers design coatings with superior adhesion, durability, and aesthetic quality.

Sumber Daya Industri

Tidak Ada Sumber Daya Tersedia

Kami sedang memperbarui perpustakaan sumber daya kami untuk industri ini. Periksa kembali segera atau hubungi kami untuk meminta dokumentasi khusus.

Minta DokumentasiProduk Pendukung

Contact Angle & Surface Tension

Contact Angle & Surface Tension

DCAT – Alat Ukur Sudut Kontak Dinamis dan Tensiometer

Seri DCAT menggabungkan perangkat pengukur sudut kontak dinamis dan tensiometer gaya untuk mengevalu...

Contact Angle & Surface Tension

Contact Angle & Surface Tension

HGC – Generator dan Pengontrol Kelembaban

Seri HGC menawarkan pembangkitan kelembapan mandiri dan kontrol presisi untuk ruang lingkungan beruk...

Oil Analysis

Oil Analysis

Intelligent Ferrography Lab (IFL-500 Series)

The Intelligent Ferrography Lab (IFL-500) is the world’s most advanced workstation for high-precis...

Contact Angle & Surface Tension

Contact Angle & Surface Tension

OCA – Sistem Pengukuran Sudut Kontak Optik dan Analisis Kontur

Seri OCA terdiri dari goniometer sudut kontak optik presisi tinggi yang menentukan sifat permukaan d...

Siap Menemukan Solusi yang Tepat?

Tim kami dapat membantu Anda memilih produk yang sempurna untuk Cat & Pelapis (Coating) aplikasi