Food and Beverage

Industry Overview

Key Features

Many of these facilities have a lot of water or steam being used to clean and sterilize products and packaging. Water can get into the lubrication oil and become a very troublesome contaminant. Facilities also often deal with airborne contaminants like sugar and other fine, powdery foods that can contaminate oils.

Often there are special oils used that comply with NSF standard like H1, H2 and H3. So any oil analysis must be able to handle these specialty lubricants.

Challenges

Water is one of the worst contaminants for lubrication oil. Water contamination can greatly affect the oil’s viscosity and can also lead to rusting of machine components. Traditional methods for measuring water contamination, like Karl Fischer titration, can be costly, time-consuming and impossible to use outside of a laboratory environment.

Fortunately water contamination can be measured quickly and easily using the FluidScan. The FluidScan requires only a couple drops of oil and one minute to run the analysis. Results compare quite favorably with laboratory Karl Fischer results without the need for special training, solvents and dangerous acids.

Typical Tests & Applications

Wear

Particle count- a high particle count or a rapid increase in particles can foreshadow an imminent failure.

Particle composition - it is often important to understand the elemental composition of particles in order to find out where they came from. Optical Emission Spectroscopy gives the user elemental information for up to 32 elements, from Li to Ce (varies with application).

Particle type - The size, shape and opacity of particles is used to determine if they are from cutting wear, sliding wear, fatigue wear, nonmetallic or fibers. This allows operators to determine the type of wear debris, wear mode and potential source from internal machinery components.

Ferrous wear - Ferrous wear measurement is a critical requirement for monitoring machine condition. The high sensitivity magnetometer measures and reports ferrous content in ppm/ml, and provides ferrous particle count and size distribution for large ferrous particles.

Chemistry

Total Acid Number (TAN) - TAN is measured to determine the corrosive potential of lubrication oils. If the TAN gets too high the oil can induce corrosion of machine parts and should be changed.

Viscosity - The main function of lubrication oil is to create and maintain a lubrication film between two moving metal surfaces. Insuring the viscosity is within recommended ranges is one of the most important tests one can run on lube oil.

Contamination

Water- Water contamination in industrial oils can cause severe issues with machinery components. The presence of water can alter the viscosity of a lubricant as well as cause chemical changes resulting in additive depletion and the formation of acids, sludge, and varnish.

Industry Resources

No Resources Available

We're currently updating our resource library for this industry. Check back soon or contact us to request specific documentation.

Request DocumentationSupporting Products

Oil Analysis

Oil Analysis

AQUA 40.00 Vario

The AQUA 40.00 Vario is a versatile Karl Fischer moisture analyzer designed for precise determinatio...

Oil Analysis

Oil Analysis

Aquamax KF Plus

The Aquamax KF Plus is a compact Coulometric Karl Fischer titrator designed for precise measurement ...

Oil Analysis

Oil Analysis

Aquamax KF PRO LPG

The Aquamax KF PRO LPG is a specialized coulometric Karl Fischer titrator tailored for determi...

Oil Analysis

Oil Analysis

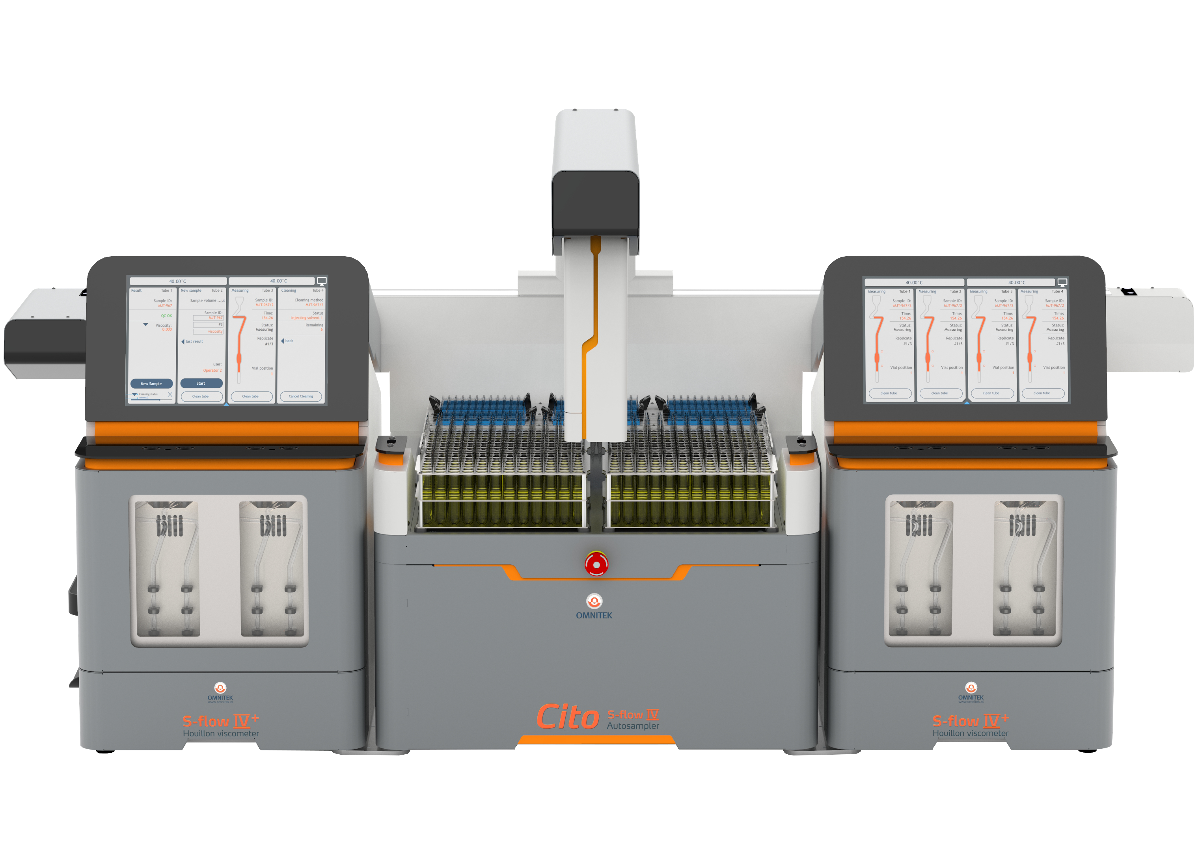

Cito Autosampler for S-flow IV

The Cito Autosampler is a high-speed, modular robotic arm designed to fully automate the sample inje...

Oil Analysis

Oil Analysis

FluidScan® 1000 Series

The FluidScan is a handheld infrared spectrometer used for on-site oil condition analysis. It measur...

Oil Analysis

Oil Analysis

Intelligent oil analyzer IOA8000

The IOA8000 is a portable, user-friendly energy-dispersive X-ray fluorescence (EDXRF) analyzer tailo...

Oil Analysis

Oil Analysis

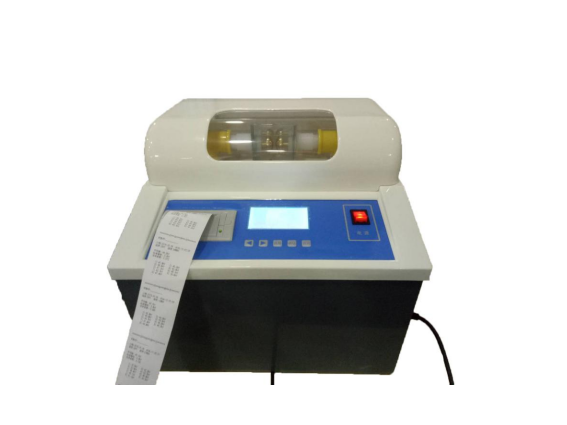

JKJQ‑1 Insulating Oil Dielectric Strength Tester

The JKJQ‑1 is a fully automatic dielectric strength tester designed to evaluate the breakdown volt...

Oil Analysis

Oil Analysis

JKJQ‑1B Dielectric Strength Tester

The JKJQ‑1B is a fully automatic, single-cup dielectric strength tester for insulating oils, ideal...

Sample Preparation

Sample Preparation

LP 200

The LP 200 is a fully automatic metallographic sample grinder meticulously designed to prepare fla...

Contact Angle & Surface Tension

Contact Angle & Surface Tension

MBP – Bubble Pressure Tensiometer

The MBP 200 by DataPhysics Instruments employs the maximum bubble pressure method to accurately me...

Oil Analysis

Oil Analysis

MicroLab Series

The MicroLab Series from Spectro Scientific is a fully automated, on-site oil analysis system design...

Oil Analysis

Oil Analysis

MiniLab 23

The MiniLab 23 is a compact, portable oil analysis system offering viscosity and fluid chemistry (...

Oil Analysis

Oil Analysis

MiniVisc 3000

The MiniVisc 3000 is a groundbreaking portable kinematic viscometer that delivers laboratory-grade v...

Oil Analysis

Oil Analysis

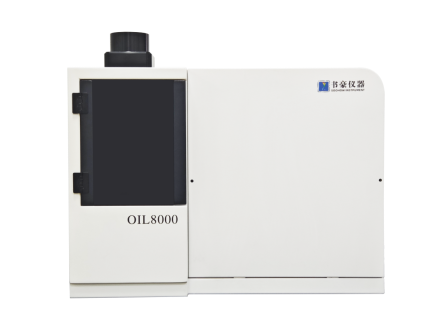

Oil spectrometer OIL8000

The OIL8000 is a compact, rotating disc electrode atomic emission spectrometer ideal for rapid eleme...

Oil Analysis

Oil Analysis

Oil spectrometer PO200

The PO200 is a Rotating Disc Electrode (RDE) Optical Emission Spectrometer tailored for rapid and di...

Oil Analysis

Oil Analysis

Pi Raptor Portable

The Raptor Portable Dry Powder Particle Size & Shape Analyzer is the first truly portable system tha...

Oil Analysis

Oil Analysis

Pi Sentinel PRO

The SentinelPro is a high-performance dynamic image analyzer designed for applications where particl...

Oil Analysis

Oil Analysis

Portable Kinematic Viscometer VS800

The VS800 Portable Kinematic Viscometer is a precision, multi-purpose viscosity measurement tool des...

Oil Analysis

Oil Analysis

Portable oil particle counter SLPC300

The SLPC300 is a portable oil particle counter that utilizes the light-blocking principle to measure...

Oil Analysis

Oil Analysis

R4 RotrOil (Automatic Sample Changer)

The R4 RotrOil is an advanced, fully automated version of GNR's RotrOil elemental spectrometer. It i...

Oil Analysis

Oil Analysis

S-flow IV⁺ Kinematic Viscometer

The S‑Flow IV⁺ is a compact, fully automated Houillon-type kinematic viscometer designed for r...

Oil Analysis

Oil Analysis

Smart Lu A

Smart Lu A is a compact and field-ready MiniLab system designed for rapid and comprehensive oil ...

Oil Analysis

Oil Analysis

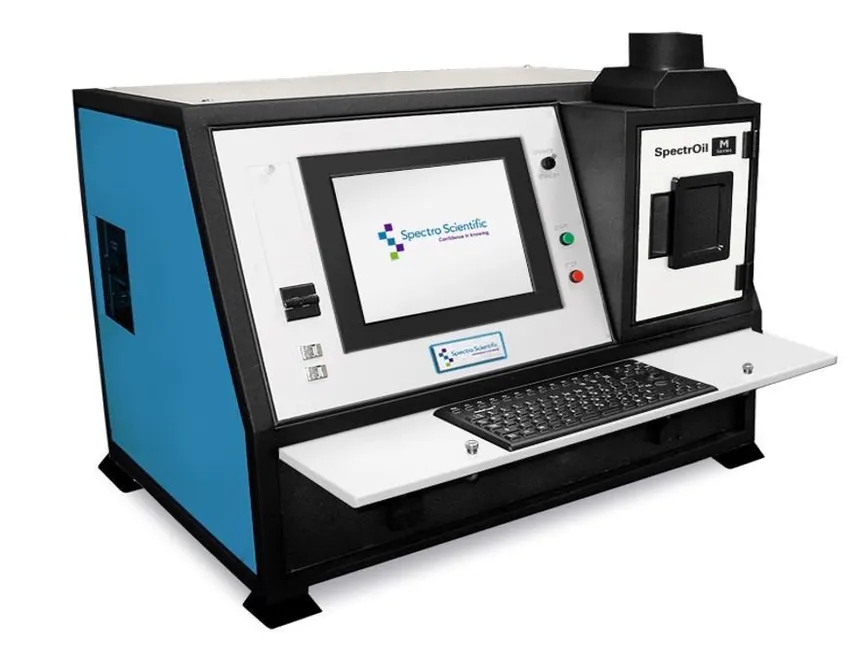

SpectrOil M Series

The SpectrOil M Series is a compact, rugged, and highly reliable Rotating Disc Electrode Optical E...

Oil Analysis

Oil Analysis

VS600 Portable Rapid Motion Viscometer

The VS600 Portable Rapid Motion Viscometer is a high-efficiency field instrument designed for fast a...

Ready to Find the Right Solution?

Our team can help you select the perfect products for your Food and Beverage applications